Truck Air Ride Suspension: Everything You Need to Know

Are you tired of dealing with bumpy rides and rough terrain in your truck? Look no further, because truck air ride suspension might just be the solution you’ve been waiting for. In this comprehensive guide, we will explore what truck air ride suspension is, its advantages, the components involved, and how it works. We will also discuss common problems you might encounter, as well as maintenance tips to keep your suspension system in top shape. If you’re ready to transform your truck’s ride quality, stay tuned as we delve into how to upgrade your truck’s suspension and the benefits of upgrading to truck air ride suspension.

What is Truck Air Ride Suspension?

Truck Air Ride Suspension is a type of suspension system that uses airbags or air springs to support and adapt to the weight of the vehicle. It is a popular choice among truck owners who want a smoother and more comfortable ride, especially when carrying heavy loads or towing trailers. The air springs are inflated with compressed air, providing adjustable support to the vehicle and reducing the impact of bumps and road vibrations.

One of the advantages of Truck Air Ride Suspension is its ability to improve ride quality and comfort. The air springs can be adjusted to different levels of firmness or softness, allowing drivers to customize their ride experience based on their preferences. This is especially beneficial for long-haul truck drivers who spend hours on the road and need a suspension system that can help reduce fatigue and improve overall comfort.

Another important component of Truck Air Ride Suspension is the air compressor, which is responsible for supplying compressed air to the air springs. The air compressor is typically controlled by an electronic air suspension management system, which monitors the vehicle’s weight and adjusts the air springs accordingly. This ensures that the suspension system is always providing optimal support and performance, regardless of the load or road conditions.

- Improved ride quality

- Adjustable support

- Reduced impact of bumps and vibrations

- Customizable ride experience

- Reduced driver fatigue

- Optimal support and performance

| Component | Description |

|---|---|

| Air Springs | Provide adjustable support and cushioning |

| Air Compressor | Supplies compressed air to the air springs |

| Electronic Air Suspension Management System | Controls the air compressor and adjusts the air springs |

In conclusion, Truck Air Ride Suspension is a suspension system that uses airbags or air springs to provide adjustable support and improve ride quality for trucks. Its advantages include improved comfort, customizable ride experience, and optimal support and performance. With its various components working together, Truck Air Ride Suspension offers a smoother and more comfortable ride for truck owners, especially when carrying heavy loads or towing trailers.

Advantages of Truck Air Ride Suspension

The advantages of truck air ride suspension are numerous and can greatly enhance the performance and comfort of your vehicle. This type of suspension system uses air springs or airbags to provide a smooth and adjustable ride. By replacing traditional steel springs with airbags, truck air ride suspension offers several benefits over conventional suspension systems.

One of the main advantages of truck air ride suspension is its ability to provide a customizable ride. With air springs, you can easily adjust the height and firmness of your vehicle’s suspension. This means you can customize the ride to suit your specific needs and preferences. Whether you’re hauling heavy loads or driving on uneven terrain, you can easily adjust the air pressure in the springs to ensure a smooth and comfortable ride.

Another advantage of truck air ride suspension is its improved load carrying capacity. Air springs are designed to better distribute the weight of the load, resulting in a more stable and balanced ride. This can be especially beneficial when you’re carrying heavy cargo or towing a trailer. The airbags can help prevent sagging, improve stability, and reduce the strain on other components of the vehicle.

Furthermore, truck air ride suspension offers increased shock absorption. The air springs are able to absorb bumps and vibrations more effectively than traditional steel springs. This not only improves the overall ride comfort but also reduces the impact on the vehicle’s chassis and other components. By reducing the amount of stress and vibration transferred to the vehicle, air ride suspension can help extend the lifespan of various parts, resulting in reduced maintenance and repair costs.

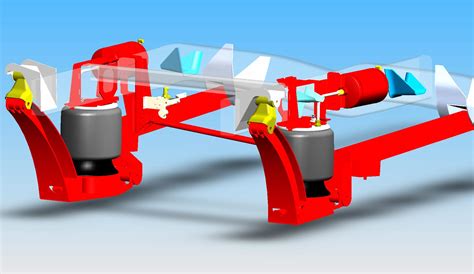

Components of Truck Air Ride Suspension

A truck air ride suspension system consists of various components that work together to provide a comfortable and smooth ride. These components play a crucial role in maintaining stability, improving handling, and reducing road vibrations for truck drivers. Understanding the different elements of a truck air ride suspension system can help you make informed decisions regarding maintenance, upgrades, and repairs.

1. Air Springs: Also known as airbags or air bellows, air springs are the cornerstone of a truck air ride suspension system. These flexible and durable bags are typically made of reinforced rubber or polyurethane and are responsible for supporting the weight of the truck. Air springs are filled with compressed air, which can be adjusted to control the ride height and stiffness of the suspension.

2. Shocks: Shocks, or shock absorbers, are crucial components that help dampen vibrations and control the movement of the suspension. They work in combination with the air springs to absorb bumps and ensure a smoother ride. Shocks convert the kinetic energy generated by the movement of the suspension into heat energy, dissipating it effectively.

3. Compressor: The compressor is responsible for supplying compressed air to the air springs. It maintains the desired air pressure within the air suspension system. The compressor automatically adjusts the air pressure based on the load and road conditions, ensuring optimal performance and comfort. A compressor can be driven by the truck’s engine or powered electrically.

4. Valves: Valves serve as control units in a truck air ride suspension system. They regulate the flow of compressed air to the air springs, allowing for adjustment in ride height and stiffness. Valves can be manually operated or controlled electronically, depending on the specific suspension system.

5. Air Lines and Fittings: Air lines and fittings connect the various components of the air ride suspension system, allowing the smooth transfer of compressed air. These lines and fittings need to be properly sealed and maintained to prevent air leaks and ensure the system functions optimally.

6. Control Switches and Sensors: Control switches and sensors play an essential role in monitoring and adjusting the truck’s air ride suspension system. They provide valuable feedback on the ride height, air pressure, and various other parameters, allowing the driver to make necessary adjustments. Control switches and sensors can be located inside the truck’s cabin for easy access and operation.

By understanding the components of a truck air ride suspension system, you can better appreciate the technology behind it and make informed decisions regarding maintenance and upgrades. Regular inspections, proper maintenance, and timely repairs can help prolong the lifespan of your suspension system, ensuring a comfortable and safe ride for both you and your truck.

| Component | Function |

|---|---|

| Air Springs | Support the weight of the truck and provide adjustable ride height |

| Shocks | Dampen vibrations and control the movement of the suspension |

| Compressor | Supply compressed air to the air springs and maintain desired air pressure |

| Valves | Regulate the flow of compressed air to adjust ride height and stiffness |

| Air Lines and Fittings | Connect various components, ensuring smooth transfer of compressed air |

| Control Switches and Sensors | Monitor and adjust the suspension system based on ride height and air pressure |

Working Principle of Truck Air Ride Suspension

The working principle of truck air ride suspension is a crucial aspect to understand for truck owners or enthusiasts. This advanced suspension system is designed to provide a smoother and more comfortable ride compared to traditional suspension setups. To comprehend how it works, it is essential to dive into the key components and functionality of truck air ride suspension.

1. Air Springs: The heart of the truck air ride suspension system lies in the air springs. These flexible rubber bellows or bags are filled with compressed air to provide support and cushioning. Air springs replace the coil or leaf springs found in conventional suspensions, offering a more adjustable and responsive ride.

2. Air Compressor: To maintain the required air pressure in the system, an air compressor is employed. This compressor continuously pressurizes the air and ensures an adequate supply is available for the air springs. The compressor can be powered by the vehicle’s engine or an independent electric motor.

3. Height Sensors and Leveling Valves: Height sensors measure the position of the chassis or axles in relation to the body of the truck. These sensors provide data to the leveling valves, which control the air pressure in the air springs. The leveling valves adjust the air pressure to maintain a consistent ride height, compensating for load changes or variations in road conditions.

4. Electronic Control Unit (ECU): The ECU, also known as the air management system, plays a vital role in the working principle of truck air ride suspension. It receives inputs from the height sensors and leveling valves, and based on the data, it adjusts the air pressure in the air springs accordingly. The ECU ensures that the suspension operates smoothly and adapts to different driving conditions.

Overall, the working principle of truck air ride suspension revolves around the concept of utilizing compressed air to provide a flexible and comfortable ride. By constantly monitoring and adjusting the air pressure in the air springs, this suspension system can effectively absorb shocks, minimize vibrations, and enhance the overall stability of the truck. Understanding the working principle helps truck owners appreciate the benefits of this innovative suspension system and make informed decisions regarding its usage and maintenance.

Common Problems with Truck Air Ride Suspension

Truck air ride suspension systems are designed to provide a smoother ride, improved handling, and increased load-carrying capacity for trucks. However, like any other mechanical system, they are prone to certain problems that can affect their performance. In this blog post, we will discuss some common problems that truck air ride suspension systems may encounter.

1. Air Leaks: One of the most common problems with truck air ride suspension systems is air leaks. Over time, the air springs and air lines may develop small cracks or holes, causing air to leak out. This can result in a loss of air pressure, affecting the suspension’s ability to maintain the desired ride height and load-carrying capacity. Regular inspections and timely repairs of air leaks are essential to ensure the proper functioning of the suspension system.

2. Uneven Ride Height: Another common problem is an uneven ride height. This can occur due to various reasons, such as worn-out air springs, faulty height sensors, or improper weight distribution. An uneven ride height not only affects the comfort and stability of the truck but also puts additional stress on certain suspension components, leading to premature wear and tear.

3. Faulty Compressor: The compressor is an integral component of the truck air ride suspension system, responsible for supplying the necessary air pressure to the air springs. A faulty compressor can result in insufficient air pressure, causing the suspension to sag or fail to adjust to the load requirements. Regular maintenance and timely replacement of the compressor are essential to avoid such problems.

- 4. Poor Ride Quality: In some cases, truck air ride suspension systems may exhibit poor ride quality, despite no apparent mechanical issues. This can be attributed to improper adjustment of the suspension settings, poor shock absorber performance, or incorrect tire pressure. Ensuring proper maintenance, regular checks of suspension settings, and using appropriate shock absorbers can help improve the ride quality.

- 5. System Overloading: Overloading the truck beyond its maximum load-carrying capacity can put excessive strain on the air ride suspension system. This can lead to premature wear and tear of the suspension components, decreased ride comfort, and increased risk of system failure. It is crucial to adhere to the recommended load limits and avoid overloading to prevent such problems.

In conclusion, while truck air ride suspension systems offer numerous benefits, they are not immune to problems. Air leaks, uneven ride height, faulty compressors, poor ride quality, and system overloading are some common issues that truck owners may face. Regular inspections, proper maintenance, and timely repairs are crucial to ensure the optimal performance and longevity of the truck air ride suspension system.

| Common Problems | Solutions |

|---|---|

| Air Leaks | Regular inspections and timely repairs |

| Uneven Ride Height | Replacement of faulty components and weight distribution management |

| Faulty Compressor | Regular maintenance and timely replacement |

| Poor Ride Quality | Proper maintenance, adjustment of suspension settings, and use of appropriate shock absorbers |

| System Overloading | Adherence to recommended load limits and avoiding overloading |

Maintenance Tips for Truck Air Ride Suspension

When it comes to maintaining a truck’s air ride suspension, there are several important tips to keep in mind. Following these maintenance tips can help ensure that your truck’s suspension system functions properly and lasts for a long time.

Regular Inspection: It is essential to regularly inspect your truck’s air ride suspension system. Check for any signs of wear or damage, such as leaks, cracks, or worn-out components. Pay close attention to the air springs, air lines, and shock absorbers. If you notice any issues, it is important to address them promptly.

Keep it Clean: A clean suspension system is a happy suspension system. Regularly clean the air springs, air lines, and other components of the air ride suspension. Use a mild cleaning solution and a soft brush to remove any dirt, grime, or debris. Avoid using harsh chemicals or high-pressure water, as they could damage the components.

Inspect and Maintain Air Springs: Air springs, also known as air bags, are a crucial part of the air ride suspension system. Regularly inspect the air springs for any signs of damage or wear. Check for any leaks and ensure that the air pressure is at the recommended level. If you notice any issues, replace the air springs immediately to avoid further damage to the suspension system.

Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s guidelines and recommendations for maintenance and servicing of your truck’s air ride suspension system. These guidelines provide valuable information on when to replace components, how to properly inflate the air springs, and any specific maintenance procedures required. Following the manufacturer’s recommendations will help maximize the lifespan and performance of your truck’s suspension system.

Regular Lubrication: Proper lubrication is crucial for the smooth operation of the air ride suspension system. Apply a lubricant to the moving parts, such as the shock absorber bushings and control arm joints, as recommended by the manufacturer. This will help reduce friction and wear, ensuring that the suspension system functions optimally.

Check Alignment and Balance: A misaligned or unbalanced suspension can cause unnecessary strain on the air ride suspension system. Regularly check the alignment and balance of your truck’s suspension. If you notice any issues, have them corrected by a professional. Proper alignment and balance will help prevent premature wear and keep your truck’s suspension system in top condition.

Regularly Check Air Compressor and Air Lines: The air compressor and air lines play a crucial role in supplying and regulating air pressure in the suspension system. Regularly inspect them for any signs of leaks or damage. Check the compressor’s air filter and ensure it is clean. If you notice any issues, have them repaired or replaced by a qualified technician.

| Benefits of Maintenance Tips for Truck Air Ride Suspension: |

|---|

| Enhanced Safety: Regular maintenance of the air ride suspension system ensures that all components are in proper working condition, reducing the risk of mechanical failures and accidents on the road. |

| Improved Performance: A well-maintained suspension system provides better ride quality, stability, and handling. It enhances the overall performance of the truck, especially when carrying heavy loads. |

| Cost Savings: By regularly inspecting and maintaining your truck’s air ride suspension system, you can identify and address issues before they become major problems. This helps avoid costly repairs and prolongs the lifespan of the suspension components. |

By following these maintenance tips for your truck’s air ride suspension system, you can ensure that it functions optimally and lasts for a long time. Regular inspections, cleaning, lubrication, and following manufacturer’s guidelines are key to keeping your suspension system in top condition. Not only will this enhance the safety and performance of your truck, but it will also save you money in the long run.

How to Upgrade Your Truck’s Suspension?

Upgrading your truck’s suspension is a great way to enhance its performance and improve your overall driving experience. Whether you use your truck for work or leisure, a suspension upgrade can make a significant difference in terms of ride quality, handling, and even towing capabilities. In this article, we will explore the various options available for upgrading your truck’s suspension and the benefits they can provide.

One option for upgrading your truck’s suspension system is to install a lift kit. A lift kit raises the height of your truck’s body, allowing for larger tires and increased ground clearance. This is particularly useful if you frequently drive off-road or in rough terrain, as it can greatly improve your truck’s ability to navigate obstacles.

Another popular suspension upgrade is the installation of performance shocks and struts. These components are designed to improve your truck’s handling and stability by reducing body roll and improving traction. Performance shocks and struts can also enhance your truck’s braking capabilities, making it easier to control during sudden stops or emergency maneuvers.

Additionally, upgrading to a air ride suspension system can provide a significant improvement in ride quality and comfort. Unlike traditional suspension systems, which use metal springs, air ride suspensions use air-filled bags or bellows to support the weight of the vehicle. This allows for finer adjustments to the suspension, resulting in a smoother and more controlled ride.

When upgrading your truck’s suspension, it is important to consider your specific needs and driving preferences. If you primarily use your truck for off-roading or towing heavy loads, a lift kit and performance shocks may be the best option for you. On the other hand, if you prioritize a comfortable and smooth ride, an air ride suspension system may be more suitable.

In conclusion, upgrading your truck’s suspension can significantly enhance its performance and improve your driving experience. Whether you choose to install a lift kit, performance shocks, or an air ride suspension system, each option offers its own unique benefits. By carefully considering your needs and preferences, you can choose the right suspension upgrade to suit your truck and driving style.

Choosing the Right Air Suspension System

When it comes to upgrading your truck’s suspension, choosing the right air suspension system is crucial. With so many options available in the market, it can be overwhelming to make a decision. However, by considering a few key factors, you can ensure that you select a system that is perfect for your truck’s needs.

First and foremost, research is essential. Take the time to understand the different types of air suspension systems available, such as leaf spring, coil spring, and air bag systems. Each system has its own unique features and benefits, so it’s important to know which one will work best for your specific truck.

Secondly, consider your truck’s weight and load requirements. It’s crucial to choose an air suspension system that can handle the weight of your truck and any additional load you may be carrying. This will ensure optimal performance and safety on the road.

- Consider the ride quality – Different air suspension systems provide different levels of comfort and ride quality. If you’re using your truck for long hauls or transporting delicate cargo, prioritize a system that offers a smooth and comfortable ride.

- Look for durability and reliability – Your air suspension system should be able to withstand the rigors of daily use and various road conditions. Look for systems that are made of high-quality materials and come with warranty coverage.

- Installation and compatibility – Ensure that the air suspension system you choose is compatible with your truck’s make and model. Additionally, consider the ease of installation and whether you can do it yourself or if professional assistance is required.

To summarize, choosing the right air suspension system for your truck involves thorough research, considering your truck’s weight and load requirements, evaluating ride quality, durability, and compatibility. By taking these factors into account, you can make an informed decision and select an air suspension system that will enhance your truck’s performance and provide a comfortable ride for years to come.

Benefits of Upgrading to Truck Air Ride Suspension

When it comes to upgrading your truck’s suspension system, one option that you should definitely consider is the truck air ride suspension. This advanced suspension system offers a wide range of benefits that can greatly enhance your driving experience and the overall performance of your truck. Whether you use your truck for daily commuting or for heavy-duty hauling, upgrading to a truck air ride suspension can provide several advantages that make it a worthy investment.

One of the key benefits of upgrading to a truck air ride suspension is the improved ride quality. Traditional suspension systems can be stiff and unforgiving, making for a bumpy and uncomfortable ride, especially on rough or uneven roads. With an air ride suspension, on the other hand, your truck will be equipped with air-filled bags or chambers that can adjust the level of support and cushioning, providing a smoother and more comfortable ride. This means less fatigue and strain on both you and your truck.

In addition to better ride comfort, upgrading to a truck air ride suspension can also improve the handling and stability of your truck. The air bags in the suspension system can be adjusted to compensate for changes in load or weight distribution, allowing for better weight balance and control. This is particularly beneficial when hauling heavy cargo or towing a trailer, as it helps maintain proper suspension alignment and stability, reducing the risk of swaying or sagging.

Another advantage of upgrading to a truck air ride suspension is the ability to adjust the ride height. This feature allows you to raise or lower your truck’s suspension with ease, depending on the specific needs of your driving conditions. For example, you can raise the suspension for off-roading or when navigating rough terrains, providing increased ground clearance and improved maneuverability. On the other hand, you can lower the suspension for improved aerodynamics and fuel efficiency when driving on highways.

In summary, upgrading to a truck air ride suspension can offer a host of benefits, including improved ride comfort, enhanced handling and stability, and adjustable ride height. By investing in this advanced suspension system, you can enjoy a smoother and more comfortable ride, regardless of the road conditions, as well as better control and flexibility when hauling heavy loads. So, if you’re looking to upgrade your truck’s suspension, it’s definitely worth considering the many advantages of a truck air ride suspension.