If you are a truck driver or own a commercial truck, you are probably familiar with the importance of a smooth and comfortable ride. One way to achieve this is by investing in a commercial truck air ride system. In this blog post, we will explore the concept of a commercial truck air ride, its advantages, components, and the process of choosing and installing the right system for your truck. We will also discuss the maintenance and care needed to ensure its longevity, common issues that may arise, and troubleshooting tips. Additionally, we will explore upgrade options for enhancing your truck’s air ride system and important safety considerations to keep in mind while using it. As a truck driver, having a reliable and efficient air ride system can greatly improve your driving experience and the overall performance of your truck.

What is a commercial truck air ride?

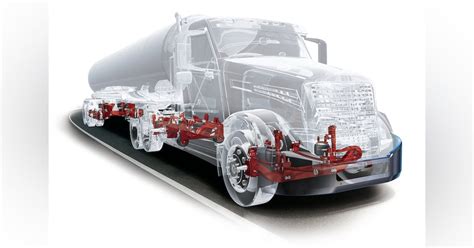

A commercial truck air ride is a type of suspension system that uses air springs or air bags to support the weight of the truck and its cargo. It is a popular choice for commercial trucks because it provides a smoother and more comfortable ride compared to traditional suspension systems. This type of suspension can be found in various types of trucks, such as semi-trucks, delivery trucks, and heavy-duty trucks.

One of the key advantages of using a commercial truck air ride is the improved ride quality. The air springs or air bags used in this system can adjust the suspension stiffness and provide a more cushioned ride. This can help reduce driver fatigue and improve overall comfort for the passengers. In addition, the air ride system can also help protect the cargo by minimizing vibrations and shocks during transport.

The components of a commercial truck air ride system include the air springs or air bags, the air compressor, the air lines, and the control valves. The air springs or air bags are usually made of durable rubber and can be inflated or deflated with air to adjust the suspension height and stiffness. The air compressor is responsible for supplying compressed air to the system, while the air lines distribute the air to the air springs or air bags. The control valves regulate the flow of air and allow for adjustments to the suspension settings.

Advantages of using a commercial truck air ride

The use of a commercial truck air ride system offers several advantages for truck owners and operators. This advanced suspension technology provides a smoother and more comfortable ride, helping to improve overall driving experience and reduce driver fatigue. Furthermore, commercial truck air ride systems enhance load protection by minimizing the impact of road vibrations and providing superior shock absorption capabilities. These systems also contribute to better fuel efficiency and increased longevity of the truck’s components, reducing maintenance costs in the long run.

One of the major advantages of a commercial truck air ride system is its ability to provide a smooth and comfortable ride for the driver and passengers. By utilizing air springs instead of traditional steel leaf springs, the air ride system can effectively reduce vibrations and bumps caused by uneven road surfaces. This not only enhances driving comfort but also allows the driver to maintain better control over the vehicle, especially during long hauls or on rough terrains.

In addition to improved ride quality, a commercial truck air ride system also offers superior load protection. The adjustable air springs can be customized to accommodate different load weights, ensuring that the cargo remains secure and undamaged throughout the journey. By minimizing the impact of road shocks and vibrations, the air ride system helps to prevent goods from shifting or being damaged during transport, ultimately saving both time and money for trucking companies.

- Smooth and comfortable ride: Air ride systems provide a smoother and more comfortable ride, reducing driver fatigue and enhancing overall driving experience.

- Enhanced load protection: Air springs minimize road vibrations, ensuring that the cargo remains safe and undamaged during transport.

- Improved fuel efficiency: The advanced suspension technology of air ride systems helps to optimize fuel efficiency, resulting in cost savings for truck owners.

- Reduced maintenance costs: By absorbing shocks and vibrations, air ride systems reduce wear and tear on the truck’s components, leading to decreased maintenance and repair expenses.

| Advantages | Description |

|---|---|

| Smooth and comfortable ride | Air ride systems provide a smoother and more comfortable ride, reducing driver fatigue and enhancing overall driving experience. |

| Enhanced load protection | Air springs minimize road vibrations, ensuring that the cargo remains safe and undamaged during transport. |

| Improved fuel efficiency | The advanced suspension technology of air ride systems helps to optimize fuel efficiency, resulting in cost savings for truck owners. |

| Reduced maintenance costs | By absorbing shocks and vibrations, air ride systems reduce wear and tear on the truck’s components, leading to decreased maintenance and repair expenses. |

Components of a commercial truck air ride

A commercial truck air ride system consists of various components that work together to provide a smooth and comfortable ride for both the driver and the cargo. These components play a crucial role in ensuring the overall performance and effectiveness of the air ride system. Let’s take a closer look at some of the key components that make up a commercial truck air ride system.

1. Air Springs: Air springs, commonly referred to as airbags or air bellows, are the primary component of a commercial truck air ride system. These flexible bags are made of durable rubber or synthetic materials and are filled with compressed air. They are responsible for absorbing shocks and vibrations from the road surface, providing a cushioning effect and improving ride comfort.

2. Compressor: The compressor is the heart of the air ride system. It pressurizes the air that fills the air springs, allowing them to expand and contract as needed. The compressor is typically powered by the vehicle’s engine through a pulley and belt system. It ensures a constant supply of compressed air to maintain proper suspension height and adjust to varying road conditions.

3. Air Control Valve: The air control valve acts as a regulator, controlling the flow of air to and from the air springs. It allows the driver to adjust the level of air pressure in the airbag and maintain optimum suspension height. This valve is often equipped with a manual or electronic control panel inside the truck cabin for easy operation.

4. Height Control Sensors: Height control sensors are used to measure the distance between the truck chassis and the ground. These sensors provide feedback to the air control valve, allowing it to adjust the air pressure in the air springs accordingly. This helps maintain a consistent ride height and prevent the truck from sagging or bottoming out.

5. Electronic Control Unit (ECU): The electronic control unit is the brain of the air ride system. It receives information from the height control sensors and other input sources, such as speed sensors and load sensors, to continuously monitor and control the suspension. The ECU makes adjustments to the air pressure in real-time, ensuring optimal ride quality and stability.

| Component | Function |

|---|---|

| Air Springs | Absorb shocks and vibrations, provide cushioning |

| Compressor | Pressurizes air for air springs, maintains suspension height |

| Air Control Valve | Regulates air flow, adjusts air pressure in air springs |

| Height Control Sensors | Measures distance to ground, maintains consistent ride height |

| Electronic Control Unit | Monitors and controls suspension, makes real-time adjustments |

These are just a few of the essential components of a commercial truck air ride system. Each component plays a vital role in ensuring a comfortable and stable ride, reducing driver fatigue, and protecting the cargo from damage caused by excessive vibrations. Regular maintenance and inspection of these components are crucial to ensure the longevity and optimal performance of the air ride system.

Choosing the right type of air ride for your truck

When it comes to choosing the right type of air ride for your truck, there are several factors to consider. The air ride system plays a critical role in providing a comfortable and smooth ride for both the driver and the cargo. It helps in reducing the impact of bumps and vibrations on the road, resulting in a safer and more efficient transportation experience.

One of the key factors to consider when choosing an air ride system is the weight capacity. Different trucks have different weight capacities, and it is crucial to select an air ride system that can handle the weight of your truck and the cargo it carries. It is recommended to consult the manufacturer’s guidelines or speak to a professional to determine the appropriate weight capacity for your specific truck.

Another important consideration is the type of suspension system. There are two common types of air ride systems: the leaf spring suspension and the air bag suspension. The leaf spring suspension is a traditional suspension system that uses a set of metal plates (leaf springs) to support the weight of the truck. On the other hand, the air bag suspension uses air bags or air springs to provide support and absorb shocks.

Benefits of using the air bag suspension include a smoother ride, better weight distribution, and improved handling. It is also known for its ability to adjust the suspension height, which can be advantageous in certain situations, such as loading and unloading cargo. However, it is important to note that the air bag suspension may come at a higher cost compared to the leaf spring suspension.

In addition to weight capacity and suspension type, it is crucial to consider the compatibility of the air ride system with your specific truck make and model. Not all air ride systems are designed to fit every truck, so it is important to ensure that the system you choose is compatible with your truck’s specifications. Consulting with a professional or referring to the manufacturer’s guidelines can help you make an informed decision.

Overall, choosing the right type of air ride system for your truck is essential for a comfortable and safe ride. Considering factors such as weight capacity, suspension type, and compatibility with your truck can help you make the best choice. By investing in the appropriate air ride system, you can enhance the performance and longevity of your truck while providing a comfortable experience for both you and your cargo.

- Weight capacity

- Type of suspension system

- Compatibility with your specific truck make and model

| Factors to consider when choosing the right type of air ride for your truck: |

|---|

| Weight capacity |

| Type of suspension system |

| Compatibility with your specific truck make and model |

Installation process of a commercial truck air ride

Installing a commercial truck air ride system can greatly enhance the comfort and performance of your vehicle. It is a worthwhile investment for truck owners who frequently transport heavy loads or travel long distances. In this blog post, we will discuss the step-by-step installation process of a commercial truck air ride system.

List of Components:

Before beginning the installation, ensure that you have all the necessary components for the air ride system. These may include:

- Air springs or airbags

- Air compressor

- Air tank

- Control panel or valves

- Pressure sensors

- Wiring harness

- Hoses and fittings

Step 1: Preparation

Start by preparing your truck for the installation process. Make sure to park it on a flat surface and engage the parking brake. Gather all the necessary tools and equipment, such as wrenches, screwdrivers, and a drill, to facilitate the installation.

Step 2: Removing Existing Suspension

The next step is to remove the existing suspension components from the truck. This usually involves disconnecting the shock absorbers, leaf springs, and any other parts that are no longer needed. Follow the manufacturer’s instructions or consult a professional if needed.

Step 3: Installing Air Springs

Once the old suspension has been removed, it’s time to install the new air springs or airbags. These will be responsible for providing the adjustable support and cushioning for your truck. Follow the manufacturer’s instructions to position and secure them correctly.

Step 4: Mounting the Compressor and Air Tank

The air compressor and air tank are crucial components of the air ride system. Mount the compressor in a secure location, such as near the engine compartment or under the truck bed. Place the air tank in a suitable position, such as the frame rails, using mounting brackets.

Step 5: Connecting Valves and Control Panel

Connect the control panel or valves to the air springs and the air tank. These will enable you to adjust the air pressure in the springs and control the ride height. Follow the manufacturer’s instructions to ensure proper connections and functionality.

Step 6: Wiring and Testing

Complete the installation by wiring the system to the truck’s electrical system. Connect the wiring harness to the control panel, compressor, and pressure sensors. Before operating the air ride system, test all connections and functionality to ensure everything is working correctly.

By following these installation steps, you can enjoy the benefits of a commercial truck air ride system. It is recommended to consult the manufacturer’s instructions and seek professional assistance if needed to ensure a successful installation. Remember, proper installation is essential for optimal performance and longevity of your truck’s air ride system.

Maintenance and care for a commercial truck air ride

A commercial truck air ride is a type of suspension system that uses air springs or airbags to support and cushion the weight of the truck and its cargo. This system is commonly used in commercial trucks to provide a smooth and comfortable ride, improve stability and control, and reduce wear and tear on the truck and its components.

Proper maintenance and care for a commercial truck air ride system is crucial to ensure its optimal performance and longevity. Regular inspections and servicing can help identify any potential issues and prevent costly repairs or replacements in the future. Here are some important maintenance and care tips to keep in mind:

- Regular inspections: Inspect the air ride system, including the air springs, air lines, valves, and controls, at regular intervals. Look for any signs of wear, damage, or leaks. Pay close attention to the airbags for any signs of cracks or punctures. Inspect the mounting brackets and bolts for tightness and proper alignment.

- Air spring maintenance: Inspect the air springs for proper inflation and adjust as needed. Over or under-inflated air springs can affect the overall performance and comfort of the ride. It is recommended to consult the manufacturer’s guidelines or a professional technician for the ideal inflation pressure.

- Keep it clean: Clear any debris or dirt from the air ride components, especially around the air springs and valves. This helps prevent any contamination or damage to the system. Be sure to clean the air lines and valves to ensure proper airflow and function.

In addition to regular maintenance, there are certain safety considerations to keep in mind when using a commercial truck air ride. It is important to follow the manufacturer’s guidelines and recommended capacity limits for your specific air ride system. Overloading the truck or exceeding the recommended weight limits can put excessive stress on the airbags and other components, leading to premature wear and potential failures.

By following proper maintenance and care practices, you can ensure that your commercial truck air ride system remains in optimal condition. This not only enhances the overall performance and ride quality of your truck but also improves safety and helps avoid costly repairs or replacements. Remember to consult the manufacturer’s guidelines or seek professional assistance for any specific maintenance requirements of your air ride system.

Common issues and troubleshooting for air ride systems

Commercial truck air ride systems offer numerous benefits, such as improved ride quality, reduced wear and tear on the vehicle, and increased driver comfort. However, like any other mechanical system, air ride systems are prone to certain issues and malfunctions. In this blog post, we will discuss some common issues that you may encounter with your truck’s air ride system and provide troubleshooting tips to help you address these problems effectively.

One of the most common issues with air ride systems is air leaks. Air leaks can occur in various components of the system, such as air springs, valves, fittings, or air lines. When there is a leak, the system may lose air pressure, causing the truck to sit lower than normal and compromising the overall performance of the air ride system. To identify and fix an air leak, it is important to inspect all the components of the system and check for any visible signs of damage or wear. Regular maintenance and inspection of the air ride system can help prevent air leaks from occurring in the first place.

Another issue that truck owners may encounter is uneven ride height. This problem can result from several factors, including worn-out air springs, faulty height sensors, or improper weight distribution. When the ride height is uneven, it can affect the stability and handling of the truck, leading to an uncomfortable and potentially unsafe driving experience. To troubleshoot this issue, it is essential to check the condition of the air springs, ensure that the height sensors are functioning correctly, and distribute the load evenly throughout the truck. By addressing these underlying causes, you can restore the proper ride height of your truck’s air ride system.

Additionally, electrical problems can also occur in air ride systems. These problems may manifest as issues with the compressor not turning on, the control module malfunctioning, or the system not responding to height adjustments. When faced with electrical problems, it is crucial to inspect the wiring connections, fuses, and switches associated with the air ride system. Ensure that all the electrical components are properly connected and functioning. If necessary, consult a professional technician or refer to the system’s user manual for guidance on troubleshooting electrical problems.

When dealing with common issues in air ride systems, it is important to remember that proper maintenance and regular inspections play a vital role in preventing and addressing these problems. By taking proactive measures, such as checking for air leaks, maintaining proper ride height, and keeping the electrical components in good condition, you can ensure the optimal performance and longevity of your truck’s air ride system. Moreover, consulting with experienced professionals and following manufacturer guidelines will help you troubleshoot and resolve any issues effectively and efficiently.

Upgrade options for enhancing your truck’s air ride system

When it comes to enhancing a commercial truck’s air ride system, there are several upgrade options available that can greatly improve the performance and comfort of the ride. These upgrades can range from simple adjustments to more complex modifications, depending on the specific needs and preferences of the truck owner. In this blog post, we will explore some of the upgrade options that can help enhance a truck’s air ride system, providing a smoother and more enjoyable driving experience.

One popular upgrade option for enhancing a truck’s air ride system is the installation of adjustable air springs. These springs allow the truck owner to adjust the stiffness of the suspension to their liking, providing a more customized and comfortable ride. By simply adjusting the air pressure in the springs, drivers can easily modify the ride according to the road conditions or their personal comfort preferences.

Another upgrade option to consider is the installation of an onboard compressor and air control system. This system allows for more precise control over the air ride system, with the ability to adjust the suspension on the go. With the push of a button, truck owners can easily raise or lower the truck’s suspension, making it easier to navigate through various terrains or loading docks.

In addition to adjustable air springs and onboard air control systems, another popular upgrade option is the installation of shock absorbers specifically designed for air ride systems. These shock absorbers work in tandem with the air springs to further enhance the ride quality and stability of the truck. They provide additional damping and support, reducing vibrations and minimizing the impact of bumps and road irregularities on the truck.

List of Upgrade Options:

- Adjustable air springs

- Onboard compressor and air control system

- Shock absorbers specifically designed for air ride systems

Table of Upgrade Options:

| Upgrade Option | Description |

|---|---|

| Adjustable air springs | Allows for adjusting the stiffness of the suspension for a more customized ride |

| Onboard compressor and air control system | Enables precise control and adjustment of the air ride system on the go |

| Shock absorbers specifically designed for air ride systems | Enhances ride quality and stability by providing additional damping and support |

These are just a few upgrade options available to enhance a truck’s air ride system. The choice of upgrade will depend on the specific needs and preferences of the truck owner. It is important to consider factors such as budget, intended usage, and desired level of comfort when selecting the appropriate upgrade option. By investing in these enhancements, truck owners can greatly improve the performance and overall experience of their commercial truck’s air ride system.

Safety considerations when using a commercial truck air ride

When it comes to using a commercial truck air ride, safety should always be a top priority. Understanding and following proper safety considerations is essential to prevent accidents and ensure the well-being of both the driver and other road users.

One crucial safety consideration is to regularly inspect the air ride system. This includes checking for any signs of wear and tear, such as damaged or leaking airbags, loose or broken components, or worn-out shock absorbers. It is recommended to inspect the air ride system before each journey to identify any potential issues that could compromise safety.

Additionally, maintaining correct air pressure in the system is vital for safe operation. Truck owners should regularly check and adjust the air pressure according to the manufacturer’s guidelines. Insufficient air pressure can lead to poor suspension performance, affecting the handling and stability of the vehicle. On the other hand, excessive air pressure can raise the risk of airbags bursting, causing a hazardous situation on the road.

Proper load distribution is another safety consideration when using a commercial truck air ride. Incorrectly loaded cargo can impact the balance and stability of the truck, potentially leading to accidents. Drivers should ensure that the weight is evenly distributed and within the recommended limits for their specific air ride system.

- Regularly inspect the air ride system

- Maintain correct air pressure

- Ensure proper load distribution

| Safety Considerations for Commercial Truck Air Ride |

|---|

| 1. Regularly inspect the air ride system |

| 2. Maintain correct air pressure |

| 3. Ensure proper load distribution |

Moreover, drivers should be cautious of their speed and driving behavior when using a commercial truck air ride. The enhanced suspension system provides a smoother ride, but it is essential to handle the vehicle responsibly. Maintaining a safe speed and avoiding sudden maneuvers can help prevent accidents and maintain control over the truck.

Lastly, it is crucial to stay informed about regulations and requirements concerning commercial truck air rides. Different regions or jurisdictions may have specific rules regarding the use of air ride systems, such as weight restrictions, licensing requirements, or mandatory inspections. Staying compliant with these regulations is essential to ensure both safety and legal compliance.

In conclusion, prioritizing safety when using a commercial truck air ride is of utmost importance. By regularly inspecting the air ride system, maintaining correct air pressure, ensuring proper load distribution, practicing responsible driving behavior, and staying informed about regulations, drivers can maximize safety and minimize risks associated with this advanced suspension technology.