Welcome to our blog post on truck air suspension! In this article, we will explore the basics of truck air suspension, including its key components and their roles in ensuring a smooth and comfortable ride. We will delve into the importance of air springs, air compressors, air valves, height control valves, air tanks, and shock absorbers in the overall functioning of the suspension system. Additionally, we will provide some valuable maintenance tips to help ensure the longevity and optimal performance of your truck’s air suspension components. So, let’s dive in and enhance our understanding of this crucial feature in trucking!

Understanding the Basics of Truck Air Suspension

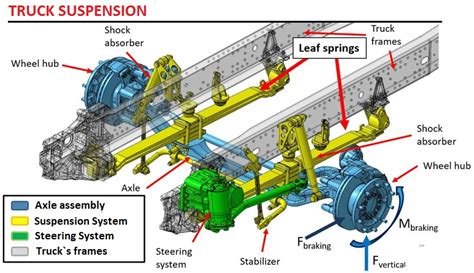

Truck air suspension plays a crucial role in the overall performance and functionality of heavy-duty vehicles. It involves a system of interconnected components that work together to provide a smooth and comfortable ride, as well as improved handling and control. To truly understand the basics of truck air suspension, it is important to have a clear understanding of its key components and how they function.

One of the primary components of a truck air suspension system is the air springs. These are rubber-like bags that are filled with compressed air and are responsible for supporting the weight of the vehicle. The air springs are typically located between the chassis and the axle, and they provide an adjustable and cushioned ride by absorbing shocks and vibrations.

The air compressor is another crucial component of truck air suspension. It is responsible for compressing the air and supplying it to the air springs. The air compressor is usually powered by the engine of the truck and ensures a continuous supply of compressed air to maintain the appropriate air pressure in the system.

The air valves are an integral part of the suspension system as well. These valves are responsible for controlling the flow of compressed air to different components of the system. They regulate the air pressure and allow for the adjustment of the suspension’s height and stiffness. By opening and closing the valves, the driver can adapt the suspension to different road conditions or loading requirements.

In addition to the key components mentioned above, truck air suspension systems also include air tanks. These tanks store and regulate the air pressure, ensuring a consistent and reliable source of compressed air. The air tanks act as a buffer, reducing the workload on the compressor and helping to maintain a stable and smooth ride.

Understanding the basics of truck air suspension is essential for truck drivers and operators, as it enables them to appreciate the role that each component plays in enhancing the performance and safety of their vehicles. By familiarizing themselves with the air springs, air compressor, air valves, and air tanks, they can identify potential issues, perform maintenance tasks, and make informed decisions when it comes to upgrading or replacing the components of their truck’s suspension system.

- Smooth and comfortable ride

- Improved handling and control

- Air springs

- Air compressor

- Air valves

- Air tanks

- Adjustment of suspension

- Reduced workload on the compressor

- Enhancing performance and safety

- Maintenance tasks

| Component | Function |

|---|---|

| Air Springs | Support the weight of the vehicle and provide a cushioned ride |

| Air Compressor | Compresses air and supplies it to the air springs |

| Air Valves | Control the flow of compressed air and regulate air pressure |

| Air Tanks | Store and regulate air pressure, act as a buffer |

Key Components of a Truck Air Suspension System

When it comes to truck air suspension systems, there are several key components that work together to provide a smooth and comfortable ride. These components not only ensure optimal performance and stability but also play a crucial role in maintaining the overall safety of the vehicle. Let’s take a closer look at some of the key components that make up a truck air suspension system.

Air Springs: One of the most important components of a truck air suspension system is the air springs. Also known as airbags or air bellows, these flexible rubber-like sacks are responsible for carrying the weight of the vehicle and adjusting its ride height. Air springs provide a cushion between the axles and the frame, absorbing shocks and vibrations to deliver a smoother and more controlled ride.

Air Compressors: Another vital component of a truck air suspension system is the air compressor. This device is responsible for pressurizing and supplying air to the air springs, allowing them to inflate and deflate as needed. The air compressor draws in outside air, compresses it, and stores it in air tanks for later use. It plays a critical role in maintaining proper air pressure in the system.

Air Valves: The air valves are essential for controlling the flow of air in the truck air suspension system. These valves regulate the air pressure and determine the amount of air that enters or exits the air springs. By opening and closing the air valves, the driver or the onboard computer can adjust the ride height and stiffness of the suspension system, improving comfort and stability.

- Air Springs: Provide cushioning and adjust ride height

- Air Compressors: Pressurize and supply air to the air springs

- Air Valves: Control the flow of air in the system

Maintenance Tips: To ensure the longevity and optimal performance of a truck air suspension system, regular maintenance is crucial. Some key maintenance tips include:

- Regularly inspecting the air springs for cracks or leaks

- Checking the air compressor and air valves for proper functioning

- Keeping the air tanks clean and free of moisture

- Periodically checking and adjusting the air pressure in the system

- Following the manufacturer’s guidelines for maintenance and service intervals

| Component | Function |

|---|---|

| Air Springs | Provide cushioning and adjust ride height |

| Air Compressors | Pressurize and supply air to the air springs |

| Air Valves | Control the flow of air in the system |

Understanding the key components of a truck air suspension system is essential for any truck owner or operator. By having a good knowledge of these components and their functions, you can better maintain and troubleshoot your suspension system, ensuring a safe and comfortable ride for you and your cargo.

The Role of Air Springs in Truck Suspension

Air springs, also known as airbags or air ride suspension, play a crucial role in the truck suspension system. These innovative components are designed to provide a smooth and comfortable ride, while also improving the overall performance and stability of the vehicle. By understanding the role of air springs in truck suspension, drivers and truck owners can appreciate the importance of this component and ensure its proper maintenance.

One of the key functions of air springs in truck suspension is to support the weight of the vehicle and its cargo. Unlike traditional steel springs, air springs are filled with compressed air, which allows them to provide adjustable support based on the specific load requirements. By adjusting the air pressure in the springs, drivers can optimize the suspension system for different loads, ensuring optimal handling and stability on the road.

Additionally, air springs in truck suspension also contribute to a smoother and more comfortable ride. The compressed air inside the springs absorbs shocks and vibrations caused by irregularities in the road surface. This helps to minimize the impact felt by the driver and passengers, resulting in a more enjoyable and less fatiguing journey.

- Improved load carrying capacity and stability

- Adjustable support for different loads

- Enhanced ride comfort and reduced fatigue

- Minimized impact from shocks and vibrations

| Benefits of Air Springs in Truck Suspension |

|---|

| Improved load carrying capacity and stability |

| Adjustable support for different loads |

| Enhanced ride comfort and reduced fatigue |

| Minimized impact from shocks and vibrations |

How Air Compressors Power Truck Air Suspension

In a truck air suspension system, the air compressor plays a vital role in providing the necessary power to operate the suspension components. Without the air compressor, the suspension system would not be able to function effectively. Let’s take a closer look at how air compressors power truck air suspension and why they are an essential component in maintaining a smooth and comfortable ride.

1. Pressurizing the Air Springs: One of the key functions of an air compressor in a truck air suspension system is to pressurize the air springs. The air springs, also known as airbags or bellows, are the primary component responsible for supporting the weight of the truck and its cargo. By supplying compressed air to the air springs, the compressor helps maintain the desired ride height and load-carrying capacity of the truck.

2. Supplying Air to Other Suspension Components: Apart from pressurizing the air springs, the air compressor also powers other suspension components that require compressed air to function. These components include air valves, height control valves, leveling valves, and air tanks. The air compressor supplies a constant flow of pressurized air to these components, allowing them to carry out their respective functions effectively.

3. Regulating the Air Pressure: Another crucial role of the air compressor is to regulate the air pressure within the suspension system. Different driving conditions may require adjustments in the air pressure to ensure optimal ride quality and stability. The air compressor monitors and adjusts the air pressure accordingly, maintaining a balanced and comfortable ride for the truck and its occupants.

- By pressurizing the air springs

- Supplying air to other suspension components

- Regulating the air pressure

| Component | Function |

|---|---|

| Air Springs | Support the weight of the truck and maintain ride height |

| Air Valves | Control the flow of compressed air to different suspension components |

| Height Control Valves | Adjust the ride height of the truck based on load conditions |

| Air Tanks | Store and regulate the supply of compressed air in the suspension system |

In conclusion, air compressors play a crucial role in powering and maintaining the functionality of a truck air suspension system. By pressurizing the air springs, supplying air to other suspension components, and regulating the air pressure, the compressor ensures a smooth and comfortable ride for the truck and its occupants.

Exploring the Importance of Air Valves in Suspension

Air valves play a crucial role in the suspension system of a truck. They are responsible for controlling the flow of air between various components, allowing the suspension to adapt to different road conditions and driver preferences. Without air valves, the truck’s suspension would be unable to provide a smooth and comfortable ride, and the vehicle’s handling and stability would be compromised.

One of the key functions of air valves is to regulate the air pressure in the suspension system. By adjusting the air pressure, the driver can control the overall height and stiffness of the suspension. This is particularly important in trucks that carry heavy loads or operate on rough terrain. The ability to vary the air pressure ensures that the suspension can adapt to different driving conditions, providing optimal performance and safety.

Another important role of air valves is to enable quick and effective air release from the suspension system. When the truck encounters a bump or pothole, the air valves allow the excess air to escape, preventing the suspension from becoming too rigid and causing discomfort to the driver and passengers. This rapid air release helps to absorb the impact and minimize the effects of road vibrations, resulting in a smoother and more comfortable ride.

- Regulating air pressure for optimal performance

- Enabling quick and effective air release

- Contributing to a smooth and comfortable ride

- Enhancing vehicle handling and stability

| Component | Function |

|---|---|

| Air valves | Regulate air pressure and enable quick air release |

| Air springs | Support the weight of the truck and absorb road shocks |

| Air compressors | Supply compressed air to the suspension system |

| Height control valves | Maintain the desired ride height of the truck |

In conclusion, air valves are an essential component of a truck’s suspension system. They play a critical role in regulating air pressure, enabling quick air release, and contributing to a smooth and comfortable ride. Understanding the importance of air valves is crucial for truck owners and operators to ensure optimal performance, safety, and longevity of their vehicles. Regular maintenance and inspection of air valves are also necessary to detect and address any potential issues before they escalate into major problems. By prioritizing the proper functioning of air valves, truck owners can enjoy a reliable and efficient suspension system for their vehicles.

The Function of Height Control Valves in Truck Suspension

Truck Suspension: The Function of Height Control Valves

When it comes to truck suspension systems, height control valves play a crucial role in maintaining stability and controlling the vehicle’s height. These valves, also known as leveling valves or ride height control valves, are responsible for adjusting the air pressure in the air springs, which in turn affects the height of the truck. By ensuring a consistent ride height, height control valves contribute to the overall safety and performance of the truck.

One of the main functions of height control valves is to level the truck. As the load on the truck changes, the weight distribution across the axles shifts, causing an imbalance. The height control valves detect this imbalance and regulate the air pressure in the air springs to restore proper ride height. This leveling action ensures that all the wheels maintain optimal contact with the road surface, improving traction and preventing excessive tire wear. Moreover, a level truck reduces the risk of rollovers and enhances the overall stability of the vehicle.

Another important function of height control valves is to provide automatic adjustment based on load conditions. These valves continuously monitor the ride height of the truck and adjust the air pressure in the air springs accordingly. When the load on the truck increases, such as during heavy cargo transportation, the air pressure is increased to maintain the desired ride height. Conversely, when the load decreases, the air pressure is reduced to prevent the truck from riding too high. This automatic adjustment ensures a consistent and comfortable ride regardless of the load on the truck.

In addition to maintaining stability and load balance, height control valves also contribute to energy efficiency. By controlling the air pressure in the air springs, these valves help in reducing the overall energy consumption of the truck. When the truck rides at the correct height, the air springs provide optimal suspension, resulting in better fuel efficiency. This is particularly important in long-haul trucking, where even small improvements in fuel efficiency can lead to significant cost savings and reduced environmental impact.

To summarize, height control valves are essential components of truck suspension systems. They ensure stability, proper load distribution, and automatic adjustment, while also contributing to fuel efficiency. By understanding the function of height control valves, truck owners and operators can better appreciate their importance in maintaining a safe, comfortable, and efficient ride.

Air Tanks: Storing and Regulating Air Pressure in Suspension

The role of air tanks in a truck air suspension system is crucial for storing and regulating air pressure. Air tanks function as reservoirs for compressed air, ensuring a steady and constant supply for the suspension system. These tanks are typically made of durable materials such as aluminum or steel and are designed to withstand high pressure. They play a vital role in maintaining the stability, levelness, and overall performance of the suspension system.

One of the key functions of air tanks is to store compressed air. When the truck’s air compressor pumps air into the system, it is first directed into the air tanks. These tanks serve as storage containers, holding the compressed air until it is required by other components of the suspension system. The size of the air tanks may vary depending on the specific application and requirements of the truck. Larger tanks can store more air, providing a greater reserve capacity for the system.

Another important role of air tanks is to regulate air pressure. The air tanks are equipped with pressure relief valves that automatically release excess air when the pressure exceeds a certain limit. This helps to prevent over pressurization and ensures the safety and reliability of the system. Additionally, air tanks may also feature drain valves to remove moisture and debris that can accumulate inside the tanks over time. Regular maintenance and inspection of these valves are essential to ensure optimal performance and efficiency.

- Storage: Air tanks store compressed air to provide a steady supply for the suspension system.

- Regulation: Air tanks regulate air pressure and prevent over pressurization.

- Pressure relief valves: These valves release excess air to maintain system safety.

- Drain valves: Drain valves remove moisture and debris from the air tanks.

| Function | Importance |

|---|---|

| Storage | Ensures a steady and constant supply of compressed air for the suspension system. |

| Regulation | Prevents over pressurization and maintains system safety and reliability. |

| Pressure relief valves | Automatically releases excess air to prevent system damage. |

| Drain valves | Removes moisture and debris from the air tanks, ensuring optimum performance. |

Air tanks are an essential component of a truck air suspension system, providing storage and regulation of compressed air. They play a crucial role in maintaining the performance, stability, and safety of the suspension system. Regular inspection and maintenance of air tanks, along with their associated valves, are vital to ensure optimal functionality and longevity of the entire suspension system.

The Significance of Shock Absorbers in Truck Air Suspension

Shock absorbers play a crucial role in ensuring a smooth and stable ride for trucks equipped with air suspension systems. These components are responsible for reducing the impact of bumps, vibrations, and road irregularities on the vehicle’s chassis and its occupants. By dampening the oscillations caused by these external forces, shock absorbers help maintain control and stability, enhance driver comfort, and protect the integrity of the truck’s suspension system.

One of the key functions of shock absorbers is to control the movement of the suspension springs, which are responsible for absorbing and distributing the weight of the truck. When the truck encounters a bump or a pothole, the springs compress and release, causing the truck to bounce. Without shock absorbers, this bouncing motion would continue for an extended period, leading to poor stability and uncomfortable driving conditions.

Shock absorbers prevent excessive bouncing by regulating the rebound and compression of the suspension springs. When the truck’s wheels hit a bump, the shock absorbers quickly compress, absorbing the energy of the impact. This compression process converts the kinetic energy into heat, dissipating it through the shock absorber’s body. As the suspension springs rebound, the shock absorbers extend, resisting the upward motion and gradually bringing the truck back to its original position.

- Improved Control and Stability: By limiting excessive movement and vibrations, shock absorbers help the driver maintain control of the truck, especially during sudden maneuvers or emergency situations. They enhance stability by minimizing body roll, preventing the truck from tilting excessively.

- Enhanced Driver Comfort: The smooth ride offered by shock absorbers reduces the jarring and bouncing sensations experienced by the driver and passengers. This contributes to a more comfortable driving experience, reducing fatigue and enhancing overall satisfaction.

- Protection of Suspension Components: The constant movement and vibrations in the truck’s suspension system can put significant stress on various components. Shock absorbers help absorb and dampen these forces, protecting the air springs, valves, and other components from excessive wear and tear.

In addition to their primary function of dampening vibrations, shock absorbers also contribute to the overall safety of the truck. By minimizing the movement of the suspension system, they help maintain tire contact with the road surface, ensuring optimal traction and braking performance. This allows the driver to have better control over the vehicle, especially in challenging driving conditions.

In conclusion, shock absorbers are an essential component of truck air suspension systems. Their significance lies in their ability to control and dampen the motion of the suspension springs, providing a smooth and stable ride, enhancing driver comfort, and protecting the integrity of the suspension system. By understanding their role and importance, truck owners and operators can ensure proper maintenance and replacement of shock absorbers, ensuring optimal performance and safety on the road.

| Benefits of Shock Absorbers in Truck Air Suspension |

|---|

| Improved Control and Stability |

| Enhanced Driver Comfort |

| Protection of Suspension Components |

| Optimal Traction and Braking Performance |

Maintenance Tips for Truck Air Suspension Components

Truck air suspension systems are crucial for ensuring a smooth and comfortable ride. However, like any other mechanical system, they require regular maintenance to perform optimally and have a longer lifespan. In this blog post, we will explore some essential tips to keep your truck air suspension components in top condition.

1. Regular Inspection: It is important to inspect your truck air suspension components regularly. Check for any signs of wear and tear, such as cracks, leaks, or damage to the air springs, air valves, height control valves, and shock absorbers. Identifying and addressing issues early can prevent further damage and costly repairs.

2. Keep it Clean: Maintaining a clean suspension system is crucial for its efficient operation. Regularly clean the air springs, air tanks, and other components using mild soap and water. Avoid using harsh chemicals as they can damage the rubber parts of the system. Additionally, keep dirt and debris away from the components to prevent clogs and restricted airflow.

3. Lubrication: Proper lubrication is essential for the smooth functioning of various suspension components. Apply lubricating grease to the pivot points, bushings, and fittings as recommended by the manufacturer. This will help reduce friction, prevent excessive wear, and extend the lifespan of the components.

4. Follow Manufacturer’s Guidelines: Each truck air suspension system is designed to operate within specific parameters. It is crucial to follow the manufacturer’s guidelines regarding the maximum weight capacity, air pressure levels, and maintenance intervals. Ignoring these guidelines can lead to decreased performance, premature wear, and even system failure.

5. Regular Air Spring Inspection: Air springs play a vital role in supporting the weight of the truck and absorbing shocks. Regularly check the air springs for any signs of sagging, cracking, or loss of air pressure. If you notice any issues, replace the faulty springs immediately to avoid further damage to the suspension system.

6. Seek Professional Help: While regular maintenance can be done by truck owners themselves, it is advisable to seek professional help for more complex issues. Truck air suspension systems are intricate, and a trained technician can identify and address problems that may not be apparent to an untrained eye. Professional maintenance can help ensure the longevity and optimal performance of your truck’s suspension system.

| Component | Maintenance |

|---|---|

| Air Springs | Regularly inspect for wear and tear, replace if necessary |

| Air Valves | Clean and lubricate to prevent clogs and ensure smooth operation |

| Height Control Valves | Check for proper functionality and adjust as needed |

| Shock Absorbers | Inspect regularly for leakage and replace if damaged |

In conclusion, regular and proper maintenance is crucial for keeping your truck air suspension components in optimal condition. By following these maintenance tips, you can prevent costly repairs, ensure a comfortable ride, and prolong the lifespan of your truck’s suspension system. Remember to always refer to the manufacturer’s guidelines and seek professional help when needed.