Truck air suspension problems can range from minor issues to major malfunctions, causing discomfort, safety hazards, and costly repairs. In this comprehensive guide, we will walk you through the common signs of truck air suspension problems, help you understand the components involved, and provide step-by-step instructions for diagnosing and repairing various issues. From air leaks and failed compressors to faulty air springs and damaged air lines, we’ll cover it all. We’ll also discuss how to address faulty height sensors and the importance of regular maintenance to prevent future problems. Plus, we’ll give you tips on choosing the right professional for truck air suspension repairs.

Common Signs of Truck Air Suspension Problems

Truck air suspension systems play a crucial role in ensuring a smooth and comfortable ride for both drivers and passengers. However, just like any other component of a vehicle, these systems are prone to problems and malfunctions over time. It is important for truck owners and drivers to be aware of the common signs of truck air suspension problems, as early detection can help prevent further damage and costly repairs. In this article, we will discuss some of the most common signs that indicate potential issues with truck air suspension.

One of the first signs of truck air suspension problems is a noticeable decrease in ride quality. If you start feeling excessive vibrations, bumps, or jolts while driving, it may indicate that the air suspension system is not functioning properly. This can be caused by a variety of issues, such as faulty air springs, worn-out shock absorbers, or air leaks. It is important to address these problems promptly to ensure the safety and comfort of both the driver and passengers.

Another common sign of truck air suspension problems is an uneven or sagging ride height. If one corner or side of the truck appears lower than the others, it may indicate a problem with the air springs or height sensors. This can affect the overall stability and handling of the vehicle, making it essential to have the suspension system inspected and repaired by a professional as soon as possible.

In addition to the aforementioned signs, strange noises coming from the suspension system are also indicative of potential problems. If you hear squeaks, hisses, or clunks while driving or when going over bumps, it may suggest issues with the air lines, valves, or compressor. Ignoring these noises can lead to further damage and costly repairs in the long run, so it is advisable to have the suspension system examined by a qualified technician.

- Frequent vibrations, bumps, or jolts while driving

- Uneven or sagging ride height

- Strange noises coming from the suspension system

| Signs of Truck Air Suspension Problems |

|---|

| Decreased ride quality |

| Uneven or sagging ride height |

| Strange noises while driving |

Understanding the Components of Truck Air Suspension

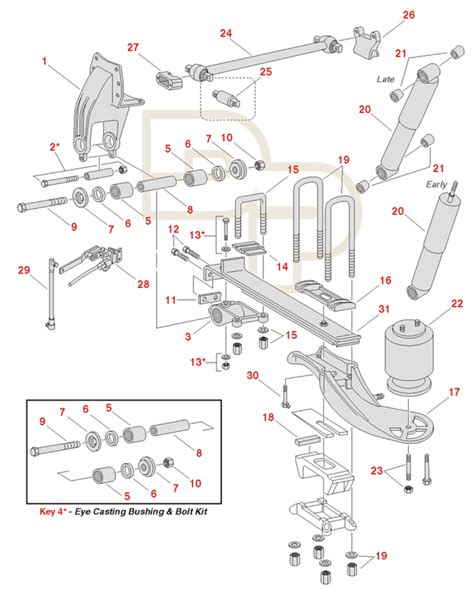

In order to fully understand and diagnose any problems with your truck’s air suspension system, it’s important to have a basic understanding of its components. The truck air suspension system consists of several key parts that work together to provide a comfortable and smooth ride. These components include:

1. Air Springs: Also known as airbags, air springs are the heart of the air suspension system. They are responsible for supporting the weight of the vehicle and providing a cushioned ride. Made of durable rubber and filled with compressed air, these springs can be adjusted to increase or decrease the height of the truck.

2. Air Compressor: The air compressor is responsible for supplying the compressed air needed to inflate the air springs. It is usually located near the engine and is powered by the vehicle’s electrical system. The compressor works by sucking in outside air and compressing it before sending it to the air springs.

3. Air Lines: The air lines connect the air compressor to the air springs, allowing the compressed air to flow through the system. Made of high-quality rubber or nylon, these lines are designed to withstand the pressure and vibrations of the air suspension system. Over time, however, they can become worn or damaged, leading to air leaks and a decrease in suspension performance.

4. Height Sensors: Height sensors are used to determine the ride height of the vehicle and adjust the air spring pressure accordingly. These sensors are typically located at each corner of the truck and send signals to the air suspension control module. By monitoring the position of the vehicle, the height sensors help maintain a consistent and level ride.

Understanding these components is crucial when it comes to troubleshooting and repairing any issues with your truck’s air suspension system. By familiarizing yourself with how each part works and interacts with the others, you can better diagnose problems and make informed decisions about repairs and maintenance. Remember, proper maintenance and regular inspections are key to keeping your truck’s air suspension system in optimal condition.

| Component | Description |

|---|---|

| Air Springs | The main components responsible for supporting the weight of the truck and providing a cushioned ride. |

| Air Compressor | Supplies the compressed air needed to inflate the air springs. |

| Air Lines | Connect the air compressor to the air springs, allowing the compressed air to flow through the system. |

| Height Sensors | Determine the ride height of the vehicle and adjust the air spring pressure accordingly. |

Diagnosing Air Leaks in Truck Air Suspension

Truck air suspension plays a crucial role in ensuring a smooth and comfortable ride. However, over time, air leaks can occur, causing various problems and compromising the overall performance of the suspension system. It is essential to diagnose and address air leaks promptly to prevent further damage and maintain the proper functioning of the suspension. This blog post will guide you through the process of identifying air leaks and taking necessary steps to resolve them.

One of the common signs of an air leak in the truck air suspension system is the constant need to refill air in the system. If you find yourself frequently adding air to the suspension, it indicates that there is a leak somewhere in the system. Another sign to watch out for is a decrease in the suspension’s ability to maintain the required pressure. If you notice that the truck’s ride quality has deteriorated or it is leaning to one side, it could be due to an air leak.

To diagnose the exact location of the air leak, start by examining the air springs. Inspect them closely for any visible damage or cracks. Additionally, check the air lines connected to the air springs for any signs of wear or looseness. Use a soapy water solution to identify air leaks. Apply the solution to the suspected areas and look for bubbles forming. These bubbles indicate the presence of a leak, helping you pinpoint its location.

- Inspect the air springs: Check for any visible damage or cracks.

- Examine the air lines: Look for signs of wear or looseness.

- Use a soapy water solution: Apply it to suspected areas and look for the formation of bubbles.

Once you have located the air leak, there are several steps you can take to repair it. For minor leaks, you may be able to fix them by applying a sealant or replacing a damaged fitting. However, if the leak is significant or the component is severely damaged, it is recommended to replace the faulty part entirely. Consult the manufacturer’s guidelines or seek professional assistance to ensure the correct repair process.

Regular maintenance is key to preventing air leaks in truck air suspension systems. Inspect the system regularly for any signs of wear or damage. Ensure that all connections are secure and free from leaks. Additionally, regularly clean and lubricate the air springs and other components to maintain their optimal functionality. By performing routine maintenance, you can minimize the risk of air leaks and prolong the lifespan of your truck’s air suspension system.

| Steps to Diagnose Air Leaks in Truck Air Suspension | |

|---|---|

| Step 1: | Inspect the air springs for visible damage or cracks. |

| Step 2: | Examine the air lines for signs of wear or looseness. |

| Step 3: | Apply a soapy water solution to the suspected areas and observe for the formation of bubbles. |

| Step 4: | Locate the air leak based on the presence of bubbles. |

| Step 5: | Repair the minor leaks with sealants or replace damaged fittings. |

| Step 6: | Consider replacing the faulty components for significant leaks or severe damage. |

Steps to Repair a Failed Air Suspension Compressor

When it comes to the air suspension system of your truck, the compressor plays a crucial role in maintaining the proper air pressure. However, over time, the compressor can fail due to wear and tear or other issues. In this blog post, we will discuss the steps to repair a failed air suspension compressor and get your truck back on the road.

Before diving into the repair process, it is important to understand the common signs that indicate a failed air suspension compressor. These signs include a noticeable drop in the ride height of your truck, difficulty in maintaining the desired level, unusual noises coming from the compressor, or simply a complete failure of the compressor. If you notice any of these signs, it is time to take action and repair the compressor.

The first step in repairing a failed air suspension compressor is to diagnose the cause of the failure. This can be done by visually inspecting the compressor for any visible damage or leaks. In addition, using a diagnostic tool can help identify any error codes related to the compressor. Once the cause of the failure is determined, you can move on to the next step.

Replacing Faulty Air Springs in Truck Air Suspension

Replacing faulty air springs in a truck’s air suspension system is an essential task that should not be overlooked. Air springs, also known as air bags, play a crucial role in providing support and stability to the truck’s suspension. These springs are responsible for absorbing shocks and bumps on the road, ensuring a smooth and comfortable ride. When air springs become damaged or worn out, it can lead to various issues and negatively affect the overall performance of the truck’s suspension system.

Common signs of faulty air springs in a truck’s air suspension:

- Uneven ride height: One of the most noticeable signs of faulty air springs is uneven ride height. If one side of the truck appears higher or lower than the other, it is a clear indication that the air spring on that side may need replacement.

- Sagging or bottoming out: When air springs lose their ability to maintain proper pressure, the truck may sag or bottom out while carrying heavy loads. This can result in reduced suspension performance and increased wear on other suspension components.

- Excessive bouncing: Faulty air springs can cause the truck to bounce excessively over bumps or rough terrain. This not only compromises the comfort of the ride but also affects the handling and stability of the vehicle.

- Air leaks: If you notice hissing sounds or air escaping from the air springs, it is likely due to an air leak. Air leaks can cause the suspension system to lose pressure, leading to a bumpy and unstable ride.

- Visible damage or wear: Inspect the air springs visually for any signs of damage, such as cracks, tears, or worn-out rubber. Damaged air springs are more prone to failure and should be replaced immediately.

Understanding the components of a truck’s air suspension system:

A truck’s air suspension system consists of several key components that work together to provide a smooth and controlled ride. These components include:

| Component | Description |

|---|---|

| Air Springs | Flexible rubber bags that hold compressed air and provide support to the truck’s suspension |

| Air Compressor | Device responsible for compressing and delivering air to the air springs |

| Air Lines | Hoses that transport compressed air from the air compressor to the air springs |

| Height Sensors | Sensors that monitor the ride height of the truck and send signals to the air compressor to adjust air pressure |

| Air Valves | Valves that regulate the flow of air in and out of the air springs to maintain proper suspension stiffness |

When replacing faulty air springs, it is important to consider the specific make and model of your truck to ensure compatibility. Consult the truck’s manufacturer or a trusted professional to determine the correct replacement parts.

It is recommended to have the replacement of air springs done by a qualified mechanic or technician with experience in truck air suspension systems. This ensures that the installation is performed correctly and that the new air springs are properly aligned and secured. Additionally, a professional will be able to diagnose any other potential issues with the suspension system and address them accordingly.

Repairing Damaged Air Lines in Truck Air Suspension

Truck air suspension plays a crucial role in providing a comfortable and smooth ride for heavy-duty vehicles. But just like any other system, it can experience issues over time. One of the common problems that truck owners may encounter is damaged air lines in the suspension. These air lines are responsible for distributing the compressed air to the air springs, allowing the suspension system to adjust and maintain the desired ride height. In this blog post, we will explore the signs of damaged air lines, understand the components of truck air suspension, and discuss the steps to repair and prevent such issues.

When it comes to damaged air lines, there are a few common signs that truck owners should be aware of. First and foremost, if you notice that your truck’s ride height is sagging or uneven, it could be an indication of a leak in the air lines. A gradual loss of air pressure can cause the suspension to lower, leading to an uncomfortable and unstable ride. Additionally, if you hear a hissing sound coming from the suspension system when the truck is running, it is a clear sign of air line damage. It’s important to address these issues promptly to prevent further damage and ensure optimal performance.

Now, let’s take a closer look at the components of truck air suspension system. It consists of several key elements, including air springs, air lines, height sensors, and an air suspension compressor. The air lines, which are typically made of flexible rubber or nylon, connect the compressor to the air springs. They carry the compressed air, allowing the suspension system to adjust its height based on the load and road conditions. It’s important to have a good understanding of these components to effectively diagnose and repair any issues with the air suspension system.

When it comes to repairing damaged air lines in truck air suspension, there are a few steps that need to be followed. The first step is to locate the damaged section of the air line. This can be done by inspecting the lines visually or using a soap and water solution to identify any air leaks. Once the damaged section is identified, it should be cut out using a sharp knife or scissors. Make sure to leave enough room on either side of the damaged area to properly connect the new section of air line. After removing the damaged section, the new air line can be installed and secured using compression fittings or clamps. It’s important to ensure a tight and secure connection to prevent any air leaks.

Preventing truck air suspension issues, including damaged air lines, can save you time and money in the long run. Regular maintenance is key to keep the system in top condition. This includes checking the air pressure regularly, inspecting the air lines for any signs of wear or damage, and ensuring proper lubrication of moving parts. If you are not confident in performing these tasks yourself, it’s advisable to consult a professional who specializes in truck air suspension repairs. They have the expertise and tools to properly diagnose and fix any issues that may arise, ensuring your truck’s suspension system operates smoothly and efficiently.

In conclusion, repairing damaged air lines in truck air suspension is an important task to ensure the optimal performance and ride comfort of heavy-duty vehicles. By being aware of the common signs of air line damage, understanding the components of the air suspension system, and following the necessary steps to repair and prevent issues, truck owners can keep their suspension system in top shape. Regular maintenance and seeking professional help when needed are crucial in maintaining a reliable and efficient truck air suspension system.

Addressing Faulty Height Sensors in Truck Air Suspension

Addressing Faulty Height Sensors in Truck Air Suspension

In a truck air suspension system, height sensors play a crucial role in maintaining the vehicle’s stability and ensuring a smooth and comfortable ride. These sensors are responsible for measuring the distance between the chassis and the ground, adjusting the air pressure in the suspension accordingly. However, like any other component, height sensors are prone to wear and tear over time, resulting in faulty readings and performance issues. Addressing these faults is essential to ensure the proper functioning of the entire air suspension system.

Faulty height sensors can be identified through common signs such as uneven ride height, excessive bouncing or sagging of the vehicle, and uneven tire wear. If you notice any of these issues, it’s crucial to address the problem promptly to avoid further damage to the suspension system and ensure your safety on the road.

The first step in addressing faulty height sensors is diagnosing the problem accurately. This involves conducting a thorough visual inspection of the sensors and their connections. Make sure to check for any loose connections or damaged wiring that may be causing the fault. Additionally, using a diagnostic tool can help identify any error codes related to the height sensors, providing valuable insights into the root cause of the problem.

- Inspect the height sensors and their connections for any damage or loose connections.

- Use a diagnostic tool to identify any error codes related to the height sensors.

- Replace faulty height sensors if necessary.

- Perform a calibration procedure after replacing the sensors to ensure accurate readings.

| Common Signs of Faulty Height Sensors | Steps to Address the Problem |

|---|---|

| Uneven ride height | Inspect height sensors and connections for damage or loose connections |

| Excessive bouncing or sagging of the vehicle | Use a diagnostic tool to identify error codes and replace faulty sensors if necessary |

| Uneven tire wear | Perform calibration procedure after replacing sensors for accurate readings |

Once you have identified the faulty height sensors, it is crucial to replace them with high-quality replacements. Ensure that you choose sensors that are compatible with your truck’s make and model, as using incorrect sensors can lead to further issues and improper suspension performance. It is recommended to seek professional assistance when replacing height sensors to ensure the correct installation and calibration.

In conclusion, addressing faulty height sensors in a truck air suspension system is crucial to maintain stability, improve ride comfort, and ensure overall safety. By understanding the common signs of faulty sensors and following the necessary steps to diagnose and replace them, you can effectively address the problem and restore the optimal performance of your truck’s air suspension system.

Performing Maintenance to Prevent Truck Air Suspension Issues

Maintaining a truck’s air suspension system is essential to ensure its optimal performance and prevent potential issues. Regular maintenance can help identify and address any problems early on, saving you time and money in the long run. In this blog post, we will discuss the importance of performing maintenance on your truck’s air suspension system and provide some useful tips to keep it in top condition.

The Components of Truck Air Suspension

Before we delve into maintenance tips, let’s briefly understand the components of a truck’s air suspension system. This system consists of several key elements, including air springs, air lines, height sensors, and an air suspension compressor. Each component plays a crucial role in maintaining the truck’s ride quality and stability on the road.

The Importance of Maintenance

Regular maintenance is vital to prevent potential issues with your truck’s air suspension system. Ignoring maintenance can lead to a variety of problems, such as air leaks, failed compressors, or damaged air springs. These issues can compromise the vehicle’s stability, ride comfort, and even safety. By performing routine maintenance, you can detect and address any problems before they escalate, ensuring a smooth and hassle-free driving experience.

Useful Tips for Maintenance

To keep your truck’s air suspension system in excellent condition, follow these maintenance tips:

- Inspect the air springs regularly for signs of wear, cracks, or leaks. Replace any damaged or worn-out springs promptly.

- Check the air lines for leaks or loose connections. Tighten connections and repair any leaks to maintain proper air pressure.

- Test the height sensors periodically to ensure accurate leveling of the truck. Adjust or replace faulty sensors to maintain stability.

- Keep the air suspension compressor clean and free from debris. Regularly inspect and replace the compressor filter to prevent clogs and avoid compressor failure.

- Follow the manufacturer’s guidelines for recommended maintenance intervals and procedures.

Choosing the Right Professional for Maintenance

While some maintenance tasks can be done by truck owners themselves, complex issues and repairs may require the expertise of a professional. When selecting a professional for truck air suspension maintenance, ensure they have the necessary experience and specialized knowledge in handling these systems. Look for certified technicians or reputable repair shops that specialize in truck air suspensions.

In Conclusion

Performing regular maintenance on your truck’s air suspension system is crucial to prevent potential issues and ensure a safe and smooth ride. By understanding the components of the system, recognizing the importance of maintenance, and following useful tips, you can keep your truck’s air suspension in excellent condition and avoid costly repairs down the road.

Choosing the Right Professional for Truck Air Suspension Repairs

When it comes to truck air suspension repairs, finding the right professional is crucial. The suspension system of a truck plays a vital role in ensuring a smooth and comfortable ride, as well as maintaining the stability and control of the vehicle. However, just like any other mechanical component, the air suspension system may encounter issues and require repairs. In such situations, it is essential to entrust the repairs to a qualified and experienced professional to ensure the job is done correctly and efficiently.

Here are a few key factors to consider when choosing the right professional for your truck air suspension repairs:

- Expertise: Look for professionals who specialize in truck air suspension repairs. They should have a thorough understanding of the various components and systems involved in truck air suspension. An expert in this field will be able to accurately diagnose the problem and provide effective solutions.

- Experience: A professional with years of experience in truck air suspension repairs has likely encountered a wide range of issues and knows how to handle them. Their experience ensures that they can efficiently identify the problem and perform the necessary repairs or replacements.

- Reputation: Do some research and read reviews or testimonials from previous customers. A reputable professional will have positive feedback, indicating their reliability, quality of work, and customer satisfaction. You can also ask for recommendations from other truck owners or industry experts.

Additionally, it is important to consider the location and convenience of the repair service. Ideally, choose a professional who is conveniently located and easily accessible. This will help minimize downtime and ensure that the repairs are done in a timely manner.

| Key Considerations | Points to Remember |

|---|---|

| Expertise | Specialization in truck air suspension repairs |

| Experience | Years of experience in handling various issues |

| Reputation | Positive reviews and customer satisfaction |

| Location | Convenient and easily accessible |

By considering these factors and conducting thorough research, you can choose the right professional for your truck air suspension repairs. Remember, it is essential to entrust your truck to a reliable and experienced individual who understands the intricacies of the air suspension system. This will ensure that your truck is in safe hands and that the repairs are carried out effectively, keeping your vehicle running smoothly on the road.