Welcome to our blog post on maintaining the performance and safety of your vehicle’s suspension system. Your vehicle’s suspension plays a crucial role in providing a comfortable ride, stability, and control. Regular inspection and maintenance are essential to ensure that your suspension continues to function properly and keeps you safe on the road. In this article, we will discuss the importance of regular inspection, checking air pressure levels, identifying and repairing leaks, inspecting for damaged airbags, keeping components clean and lubricated, replacing worn-out suspension parts, proper alignment and balancing, maintaining optimal ride height, and monitoring suspension performance. Join us as we delve into these key aspects of maintaining your vehicle’s suspension system.

Importance of Regular Inspection

Regular inspection is crucial for maintaining the overall performance and safety of your vehicle. It involves thoroughly examining various components and systems to identify any potential issues or wear and tear. By conducting regular inspections, you can catch problems early on and prevent them from escalating into more expensive and dangerous situations.

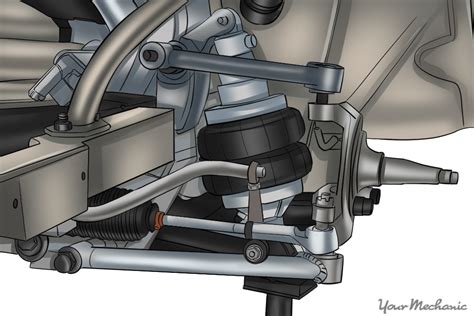

One of the key benefits of regular inspection is ensuring the proper functioning of your vehicle’s suspension system. A suspension system plays a vital role in providing a comfortable ride and keeping your vehicle stable on the road. It consists of several components, including shock absorbers, springs, struts, and control arms. Regular inspections allow you to check for any signs of damage or wear in these components.

Another important aspect of regular inspections is checking the condition of your vehicle’s tires. Proper tire maintenance is essential for maintaining optimal traction, handling, and fuel efficiency. Inspecting the air pressure levels in your tires ensures that they are properly inflated, preventing uneven tire wear, reduced tire life, and poor vehicle performance. Regular inspections also help identify any leaks in the tires, which can lead to air loss and potential blowouts.

Checking Air Pressure Levels

It is essential to regularly check the air pressure levels in your vehicle’s tires to ensure optimal performance and safety on the road. Maintaining the correct tire pressure is not only crucial for fuel efficiency but also for extending the lifespan of your tires. When your tires are underinflated, they can cause increased rolling resistance, leading to poor fuel economy and uneven tread wear. On the other hand, overinflated tires can result in reduced traction, a harsher ride, and an increased risk of a blowout. Therefore, it is important to periodically check and adjust the air pressure levels in your tires.

A simple way to check tire pressure is by using a tire pressure gauge, which can be purchased at most automotive stores or online. To properly measure the air pressure, ensure that the tires are cool and have not been driven for at least three hours. Remove the tire valve cap and firmly press the gauge onto the valve stem. The gauge will provide a reading displaying the tire pressure in pounds per square inch (psi). Compare this reading to the recommended psi specified by the vehicle manufacturer, which can usually be found on a sticker inside the driver’s side door jamb or in the owner’s manual.

Regularly inspecting your tire pressure allows you to catch any issues early on and take immediate action. If you find that the tire pressure is too low, you can inflate the tires using an air compressor or visit a nearby service station. Likewise, if the tire pressure is too high, you can release some air using the tire valve or seek assistance from a professional. Remember to check the spare tire as well, as it is often overlooked but equally important.

- Benefits of proper tire pressure:

- Improved fuel efficiency

- Enhanced handling and traction

- Extended tire lifespan

- Reduced risk of blowouts

| Tire Size | Front Tires (psi) | Rear Tires (psi) | Spare Tire (psi) |

|---|---|---|---|

| 205/55R16 | 32 | 32 | 33 |

| 225/60R17 | 34 | 34 | 35 |

| 265/70R18 | 36 | 36 | 37 |

By maintaining proper air pressure levels in your vehicle’s tires and periodically checking them, you can ensure a smoother, safer, and more efficient driving experience. Remember to check the air pressure at least once a month, as well as before long trips or during drastic weather changes. Your vehicle and your wallet will thank you for it in the long run!

Identifying and Repairing Leaks

When it comes to the smooth functioning of your vehicle’s suspension system, it is essential to pay attention to every detail. One crucial aspect that often gets overlooked is identifying and repairing leaks. Leaks can occur in various parts of the suspension system, such as the shock absorbers, struts, or air springs. These leaks can lead to decreased performance, instability, and ultimately, a compromised driving experience. In this blog post, we will explore the importance of identifying and repairing leaks promptly to maintain the optimal performance and longevity of your suspension system.

Importance of Regular Inspection

Regular inspection of your suspension system is the first step in identifying and repairing leaks. By visually inspecting the components, you can recognize any signs of leakage, such as fluid stains, dampness, or visible fluid drips. It is vital to conduct these inspections regularly to catch any leaks early on, preventing further damage to your suspension system. While a minor leak may not seem like a major concern at first, it can quickly escalate into a costly repair or even a safety hazard if left unattended.

Checking Air Pressure Levels

In some cases, leaks may occur in the air springs or air suspension system of your vehicle. These leaks can cause a decrease in air pressure, leading to an imbalance in the suspension and compromised ride comfort. To identify and repair air leaks, it is essential to check the air pressure levels regularly. Use a tire pressure gauge to measure the pressure in each air spring and compare it to the manufacturer’s recommended levels. If you notice a significant drop in pressure or uneven distribution, it is likely that there is a leak that needs to be addressed.

- Inspecting for Damaged Airbags

- Keeping Components Clean and Lubricated

- Replacing Worn-out Suspension Parts

Inspecting for Damaged Airbags

In addition to air leaks, it is also crucial to inspect the airbags themselves for any signs of damage or wear. Over time, airbags can develop cracks, tears, or punctures, leading to air leakage. Inspect the airbags visually for any visible signs of damage, such as tears in the rubber or deformation. If you notice any issues, it is crucial to address them promptly and replace the damaged airbags to maintain the structural integrity and performance of your suspension system.

Keeping Components Clean and Lubricated

Another essential aspect of preventing leaks in your suspension system is maintaining cleanliness and proper lubrication of the components. Dirt, debris, and grime can accumulate on various suspension parts, causing abrasion, corrosion, or blockage. Regularly clean the components using a gentle detergent and a soft brush to remove any buildup. Additionally, ensure that the moving parts of the suspension system are adequately lubricated to minimize friction and extend their lifespan.

Replacing Worn-out Suspension Parts

If you have identified a leak in your suspension system, it is crucial to inspect the affected parts thoroughly. In some cases, leaks may occur due to worn-out or damaged components, such as seals or gaskets. If you notice any signs of wear or if the leak persists after attempting repairs, it may be necessary to replace the worn-out parts. Consult with a professional mechanic to determine the exact cause of the leak and to ensure that the replacement parts are of high quality and compatible with your vehicle’s suspension system.

| Maintenance Tips | Preventive Measures |

|---|---|

| Regularly inspect your suspension system | Keep the components clean and lubricated |

| Check air pressure levels in air springs | Inspect for damaged airbags |

| Address any leaks promptly to prevent further damage | Replace worn-out suspension parts if necessary |

In conclusion, identifying and repairing leaks in your vehicle’s suspension system is crucial for optimal performance and safety. Conduct regular inspections, check air pressure levels, and inspect for damaged airbags to catch any leaks early on. Additionally, keep the components clean and lubricated to prevent blockages or abrasion. If leaks persist or components are worn-out, consult with a professional mechanic and replace the necessary parts. By following these preventive measures and maintenance tips, you can ensure a smooth and enjoyable driving experience while prolonging the lifespan of your suspension system.

Inspecting for Damaged Airbags

When it comes to ensuring the safety of your vehicle, one of the most crucial aspects to inspect regularly is the condition of the airbags. Airbags play a vital role in protecting both the driver and passengers in the event of a collision. In this blog post, we will discuss the importance of inspecting airbags for any signs of damage and the necessary steps to take if a problem is detected.

Damaged airbags can be ineffective in providing the desired protection during an accident. This is why regular inspection of airbags is essential to ensure their proper functioning. Visual examination is the first step to identify any visible signs of damage. Look for torn fabric, irregular bulges, or any deformities on the surface of the airbag. Additionally, check if the airbag cover is intact and not loose or sagging.

In addition to visual inspection, it is also important to check the airbag’s diagnostic system for any fault codes or warning lights on the dashboard. Fault codes indicate potential issues with the airbag system, and it is advisable to consult a professional mechanic to diagnose and repair the problem. Ignoring such warning signs can jeopardize the functioning of the airbags and compromise the safety of the vehicle occupants.

Here is a checklist to help you inspect and maintain your airbags effectively:

| Inspection Step | Action |

|---|---|

| 1. Visual Examination | Check for torn fabric, irregular bulges, or deformities on the airbag surface. |

| 2. Check Airbag Cover | Ensure that the airbag cover is intact and not loose or sagging. |

| 3. Diagnostic System Check | Monitor the dashboard for any warning lights or fault codes related to the airbag system. |

| 4. Professional Inspection | Seek the assistance of a certified mechanic to diagnose and repair any identified issues. |

Regular inspection and maintenance of airbags are vital to guarantee their optimal functioning in case of an accident. Remember, prevention is always better than cure, especially when it comes to vehicle safety. So, make it a priority to inspect your airbags frequently to ensure the highest level of protection on the road.

Keeping Components Clean and Lubricated

Keeping Components Clean and Lubricated is an essential part of maintaining the longevity and performance of your vehicle’s suspension system. Regularly cleaning and lubricating the components helps to prevent rust, corrosion, and premature wear, ensuring that your suspension system remains in top condition. In this blog post, we will discuss the importance of keeping your suspension components clean and lubricated, as well as the steps involved in doing so.

One of the main reasons to keep components clean and lubricated is to prevent rust and corrosion. Suspension components are exposed to various elements such as dirt, salt, and moisture, which can cause them to deteriorate over time. By regularly cleaning the components, you can remove any dirt or debris that may have accumulated, preventing it from causing damage. Additionally, applying lubricant to the moving parts of the suspension system helps to reduce friction and wear, allowing the components to function smoothly.

Listed below are some steps you can follow to clean and lubricate your suspension components:

| Step | Description |

|---|---|

| 1 | Start by lifting your vehicle using jack stands or a lift to gain access to the suspension components. |

| 2 | Use a hose or pressure washer to rinse off any dirt or debris from the components. Pay special attention to hard-to-reach areas. |

| 3 | After rinsing, use a mild detergent and a brush to scrub away any remaining dirt or grime. Be careful not to damage any sensitive components. |

| 4 | Once the components are clean, thoroughly dry them with a clean cloth to prevent moisture buildup. |

| 5 | Apply lubricant to the moving parts of the suspension system, such as ball joints, control arm bushings, and sway bar links. Use a suitable lubricant recommended by your vehicle’s manufacturer. |

| 6 | Finally, lower your vehicle and test the suspension system to ensure everything is working smoothly. |

In conclusion, keeping your suspension components clean and lubricated is crucial for maintaining optimal performance and longevity. By regularly cleaning and lubricating the components, you can prevent rust, corrosion, and premature wear, ensuring a smooth and safe ride. Follow the steps outlined above to keep your suspension system in top condition and enjoy a comfortable driving experience.

Replacing Worn-out Suspension Parts

The suspension system of a vehicle plays a crucial role in providing a smooth and comfortable ride. Over time, however, the suspension parts can wear out due to various factors such as normal wear and tear, driving conditions, and lack of maintenance. When this happens, it becomes necessary to replace the worn-out suspension parts to ensure the optimal performance of the suspension system.

One of the key indicators that suspension parts need to be replaced is when you experience a change in the vehicle’s handling or notice excessive vibrations while driving. Worn-out suspension parts can affect the stability and control of the vehicle, leading to unsafe driving conditions. It is important to address these issues promptly by replacing the worn-out parts.

There are several suspension parts that may need replacement, including control arms, ball joints, bushings, shocks, and struts. These components are responsible for providing stability, absorbing shocks, and maintaining proper wheel alignment. When any of these parts wear out, it can result in a bumpy and uncomfortable ride, increased tire wear, and even reduced braking efficiency.

- Control arms: These are essential in connecting the suspension system to the vehicle’s chassis. They help in maintaining wheel alignment and absorbing road shocks.

- Ball joints: These are crucial for allowing the wheels to move up and down while still maintaining proper alignment. Worn-out ball joints can cause the wheels to become misaligned and affect steering control.

- Bushings: These are used to absorb shocks and vibrations and provide a smooth ride. Worn-out bushings can lead to excessive noise, vibrations, and a loss of control.

- Shocks and struts: These components are responsible for dampening the shocks and vibrations experienced while driving. When they wear out, the vehicle may bounce excessively, making it difficult to control.

Replacing worn-out suspension parts is not a task that should be taken lightly. It is important to consult a professional mechanic who can accurately diagnose the problem and recommend the appropriate replacement parts. They will ensure that the new parts are of high quality and compatible with your vehicle’s make and model.

| Benefits of replacing worn-out suspension parts: |

|---|

| 1. Improved ride comfort: Replacing worn-out suspension parts will restore the smoothness and comfort of your vehicle’s ride, eliminating any vibrations or bumps. |

| 2. Enhanced safety: By maintaining proper wheel alignment and control, replacing worn-out suspension parts ensures safer driving conditions and improved handling. |

| 3. Longer tire life: Worn-out suspension parts can cause uneven tire wear, reducing the lifespan of your tires. Replacing these parts will help preserve the life of your tires. |

| 4. Better vehicle performance: With new suspension parts in place, your vehicle’s overall performance will improve, including better traction, smoother cornering, and more responsive braking. |

Regular inspection and maintenance of the suspension system can help prevent extensive wear and damage to the suspension parts. However, if you observe any signs of worn-out suspension parts, it is essential to take prompt action and have them replaced to ensure a safe and comfortable driving experience.

Proper Alignment and Balancing

Proper alignment and balancing are crucial factors in maintaining optimal performance and longevity of your vehicle’s suspension system. Suspension alignment refers to the correct positioning of the wheels and tires relative to the vehicle’s frame. Balancing, on the other hand, involves distributing the weight evenly across all four wheels. Neglecting proper alignment and balancing can lead to various issues, including uneven tire wear, steering problems, and decreased stability on the road.

One of the primary benefits of proper alignment and balancing is improved handling and control. When your wheels are correctly aligned, your vehicle will have better traction and stability, particularly during cornering and braking. This is especially important for high-performance vehicles or those used in off-road conditions. Proper alignment also ensures that your tires wear evenly, extending their lifespan and saving you money in the long run.

In addition to handling and control, proper alignment and balancing can also enhance fuel efficiency. When your wheels are aligned correctly, there is less resistance from the tires, resulting in reduced rolling resistance. This means your engine doesn’t have to work as hard to propel the vehicle forward, leading to improved gas mileage. Over time, this can translate into significant cost savings on fuel expenses.

- Improved handling and control

- Extended tire lifespan

- Cost savings on fuel expenses

Regular alignment and balancing also contribute to a smoother and more comfortable ride. When the wheels are properly aligned, they rotate in a straight line, ensuring a smooth contact patch between the tires and the road surface. This helps to eliminate vibrations and excessive road noise, providing a more pleasant driving experience for you and your passengers.

When it comes to aligning and balancing your suspension system, it is essential to rely on a professional and experienced mechanic. They have the expertise and specialized equipment needed to accurately measure and adjust your vehicle’s suspension components. Regular inspections and maintenance checks should be scheduled to identify any misalignment or imbalance issues and address them promptly.

| Benefits of Proper Alignment and Balancing | Summary |

|---|---|

| Improved handling and control | Proper alignment and balancing enable better traction, stability, and maneuverability of your vehicle, ensuring safer driving. |

| Extended tire lifespan | Even tire wear due to correct alignment and balancing helps prevent premature tire replacement. |

| Cost savings on fuel expenses | Reduced rolling resistance from proper alignment leads to improved fuel efficiency and reduced fuel consumption. |

| Smoother and more comfortable ride | Aligning and balancing the suspension system minimizes vibrations and road noise, resulting in a more enjoyable driving experience. |

By prioritizing proper alignment and balancing, you can ensure that your suspension system performs optimally, enhancing your vehicle’s safety, longevity, and overall driving experience. Regular inspections and maintenance, performed by a professional mechanic, remain key to identifying and addressing any alignment or balancing issues promptly.

Maintaining Optimal Ride Height

When it comes to maintaining optimal ride height in your vehicle, there are several factors to consider. Ride height refers to the distance between the ground and the bottom of your vehicle’s chassis. It plays a crucial role in ensuring a smooth and comfortable ride, as well as the overall performance of your vehicle. By taking the necessary steps to maintain optimal ride height, you can prolong the lifespan of your suspension system and enjoy a safer driving experience.

One of the key factors in maintaining optimal ride height is regularly checking and inspecting your vehicle’s suspension components. This includes the springs, shocks, and struts. Over time, these components can wear out or become damaged, leading to a decrease in ride height. By visually inspecting these parts and looking for signs of wear or damage, such as sagging or leaking, you can identify any issues early on and take appropriate action.

In addition to regular inspections, it’s important to keep your suspension components clean and properly lubricated. Dirt, debris, and rust can accumulate on these parts, which can affect their performance and lead to a decrease in ride height. By cleaning your suspension components regularly and applying lubricant where necessary, you can prevent unnecessary wear and tear and maintain optimal ride height.

- Regularly inspect your suspension components for signs of wear or damage

- Clean your suspension components to prevent dirt, debris, and rust build-up

- Apply lubricant to keep your suspension components properly lubricated

In addition to visual inspections and maintenance, it’s also important to monitor the performance of your suspension system. This can be done by paying attention to any changes in ride quality, such as excessive bouncing or a rougher ride. If you notice any unusual symptoms, it’s important to have your vehicle checked by a professional mechanic who can diagnose and repair any issues.

In conclusion, maintaining optimal ride height is essential for the overall performance and safety of your vehicle. By regularly inspecting your suspension components, keeping them clean and lubricated, and monitoring their performance, you can prolong the lifespan of your suspension system and enjoy a smoother, more comfortable ride. Remember, a well-maintained suspension system not only enhances your driving experience but also ensures your safety on the road.

Monitoring Suspension Performance

The suspension system in a vehicle plays a crucial role in ensuring a smooth and comfortable ride. It is responsible for absorbing shocks from the road and keeping the tires in contact with the ground. However, over time, the performance of the suspension system can deteriorate, leading to a decrease in ride quality and handling. To maintain optimal suspension performance, it is important to regularly monitor the condition of the suspension components and address any issues promptly.

One of the key aspects of monitoring suspension performance is to check for any noticeable changes in the vehicle’s ride quality. If you notice that your car is bouncing excessively, leaning to one side, or experiencing a rough and uncomfortable ride, it may indicate a problem with the suspension system. It is important not to ignore these signs as they can lead to further damage to the suspension components and compromise your safety on the road.

Another way to monitor suspension performance is to visually inspect the suspension components for any signs of wear or damage. Check for leaks, cracks, or corrosion on the shocks, struts, and springs. Any visible damage should be addressed immediately, as it can affect the overall performance of the suspension system. Additionally, pay attention to any unusual noises coming from the suspension while driving, such as squeaking or clunking sounds, as they may indicate a problem.

- Regular inspection: To ensure optimal suspension performance, it is recommended to perform regular inspections of the suspension system. This can be done during routine maintenance checks or when you notice any issues with the handling or ride quality of your vehicle.

- Checking air pressure levels: Proper tire inflation is essential for maintaining optimal suspension performance. Make sure to regularly check the air pressure levels in your tires and inflate them to the recommended specifications.

- Identifying and repairing leaks: Any leaks in the suspension system can lead to a loss of hydraulic fluid or air pressure, affecting the overall performance. Inspect the suspension components for any signs of leaks and have them repaired promptly.

| Importance of Regular Inspection | Checking Air Pressure Levels | Identifying and Repairing Leaks |

|---|---|---|

| Regular inspections help identify potential issues and prevent further damage to the suspension system. | Proper tire inflation helps maintain the correct ride height and improves overall suspension performance. | Repairing leaks in the suspension system prevents loss of hydraulic fluid or air pressure, ensuring optimal performance. |

Regular inspections, checking air pressure levels, and identifying and repairing leaks are some of the key measures to monitor and maintain suspension performance. By taking care of your vehicle’s suspension system, you can ensure a smoother and safer ride, as well as prolong the lifespan of your suspension components.