Introduction to Truck Air Springs

Truck air springs are an essential component for any truck owner looking to improve their vehicle’s performance and comfort. These innovative suspension systems have gained popularity due to their ability to enhance load support, reduce road vibrations, and provide a smoother ride. In this blog post, we will delve into the benefits of installing truck air springs, discuss the different types available in the market, guide you through the process of choosing the right air springs for your truck, provide a step-by-step installation guide, offer tips for proper maintenance and care, address common troubleshooting issues, and recommend top brands and products to consider. So, let’s dive in and explore the world of truck air springs together!

Introduction to truck air springs

Truck air springs, also known as airbags or air suspension systems, are essential components in the suspension system of large trucks and trailers. These air springs play a crucial role in providing a smooth and comfortable ride, as well as ensuring proper load distribution and stability.

One of the main benefits of installing truck air springs is the enhanced ride quality. By using compressed air, the air springs are able to absorb shocks and vibrations caused by uneven surfaces, potholes, or bumps on the road. This not only improves the comfort for the driver and passengers but also helps to protect the cargo from damage during transportation.

Additionally, truck air springs assist in maintaining the correct ride height and leveling the vehicle. They allow for adjustable suspension, allowing the driver to increase or decrease the air pressure based on the load being carried. This feature is particularly useful for trucks and trailers that frequently carry heavy loads or experience uneven weight distribution.

Benefits of installing truck air springs

Truck air springs are an essential component for any truck owner who wants to enhance their vehicle’s performance and ride quality. By installing truck air springs, you can enjoy a wide range of benefits that will improve the overall driving experience. In this blog post, we will discuss some of the significant benefits of installing truck air springs.

1. Increased Load Capacity:

- Truck air springs have the ability to support heavy loads, making them ideal for hauling and towing purposes.

- With air springs, you can increase your truck’s load capacity, allowing you to carry greater loads without causing strain or damage to your suspension system.

- Whether you’re transporting equipment, supplies, or any other heavy items, truck air springs will ensure a smooth and stable ride.

2. Improved Ride Quality:

- Truck air springs provide excellent shock absorption, reducing the impact of road bumps and vibrations.

- By maintaining constant air pressure in the springs, they help to minimize the jolts and discomfort that can be caused by uneven road surfaces.

- Installing air springs can result in a much smoother and more comfortable ride, particularly when driving on rough terrains or uneven roads.

3. Enhanced Vehicle Control:

- Truck air springs contribute to better vehicle stability and control.

- By adjusting the air pressure in the springs, you can fine-tune the suspension to match your specific driving preferences.

- This allows for improved handling and maneuverability, ensuring a safer and more enjoyable driving experience.

4. Extended Suspension Lifespan:

- Truck air springs help to reduce the wear and tear on your suspension system by providing added support and cushioning.

- By absorbing shocks and distributing the load evenly, they prevent excessive strain on the suspension components.

- This can result in a longer lifespan for your suspension system, saving you money on costly repairs or replacements.

In conclusion, the installation of truck air springs offers numerous benefits that can greatly enhance the performance and ride quality of your truck. From increased load capacity to improved ride comfort and vehicle control, air springs are a valuable addition to any truck. Additionally, they contribute to prolonging the lifespan of your suspension system, providing long-term cost savings. If you want to improve your truck’s capabilities and enjoy a smoother drive, consider investing in high-quality truck air springs.

Types of truck air springs

Truck air springs are an essential component of the suspension system in trucks. They play a crucial role in providing support, stability, and comfort to the vehicle. There are various types of truck air springs available in the market, each designed to cater to specific needs and applications. In this blog post, we will explore the different types of truck air springs and discuss their features, benefits, and suitability for various trucking needs.

1. Single Convolute Air Springs: These types of air springs consist of a single convoluted rubber bellow, which provides suspension support and helps in absorbing shocks and vibrations. Single convolute air springs are commonly used in light-duty and medium-duty trucks. They offer a smooth ride and are reliable in terms of maintenance and durability.

2. Double Convolute Air Springs: As the name suggests, double convolute air springs have two convoluted rubber bellows. This design allows for greater load-carrying capacity and increased height adjustability. Double convolute air springs are often used in heavy-duty trucks or vehicles that require a higher level of support and stability.

3. Sleeve Air Springs: Sleeve air springs, also known as rolling lobe air springs, consist of a cylindrical-shaped rubber sleeve that is reinforced with multiple layers of fabric. These air springs provide a high level of load support and are commonly used in heavy-duty trucks and commercial vehicles. They offer excellent ride quality and are suitable for applications that require superior load-carrying capacity.

| Type of Truck Air Springs | Features | Applications |

|---|---|---|

| Single Convolute Air Springs | Smooth ride, reliable, easy maintenance | Light-duty and medium-duty trucks |

| Double Convolute Air Springs | Greater load-carrying capacity, height adjustability | Heavy-duty trucks |

| Sleeve Air Springs | High load support, excellent ride quality | Heavy-duty trucks, commercial vehicles |

Choosing the right type of truck air springs depends on various factors such as the truck’s weight, intended use, suspension system requirements, and load-carrying capacity. It is recommended to consult with a knowledgeable professional or refer to the truck manufacturer’s guidelines to ensure the selection of the appropriate air spring type for your specific trucking needs.

By understanding the different types of truck air springs and their applications, truck owners and drivers can make informed decisions regarding the suspension system of their vehicles. Selecting the right type of air springs contributes to the overall performance, comfort, and safety of the truck, ultimately enhancing the driving experience and minimizing potential maintenance issues.

Choosing the right air springs for your truck

When it comes to choosing the right air springs for your truck, there are several factors to consider. Air springs, also known as air bags or air suspension systems, are an important component of a truck’s suspension system. They provide support and cushioning to the vehicle, improving ride comfort and handling. However, not all air springs are created equal, and different trucks have different requirements. In this blog post, we will discuss the key considerations to keep in mind when selecting air springs for your truck.

1. Weight Capacity:

The weight capacity of the air springs is one of the most important factors to consider. Different trucks have different weight capacities, and it is crucial to choose air springs that can support the weight of your specific truck, including any additional load or cargo. Exceeding the weight capacity can lead to poor performance and potential damage to the air springs.

2. Ride Quality:

The ride quality is another important factor to consider when selecting air springs. Some air springs are designed for a smooth and comfortable ride, while others prioritize load-carrying capacity or off-road performance. Think about your specific needs and preferences, and choose air springs that provide the desired level of ride quality.

3. Durability and Construction:

The durability and construction of the air springs play a significant role in their performance and lifespan. Look for air springs that are made from high-quality materials and feature a robust construction. Consider factors such as resistance to corrosion, weather conditions, and vibrations. It is recommended to choose air springs from reputable brands known for their quality and reliability.

4. Compatibility:

Ensure that the air springs you choose are compatible with your truck’s make and model. Different trucks may require specific mounting brackets or hardware for proper installation. It is essential to check the manufacturer’s compatibility charts or consult with a trusted mechanic to ensure a proper fit.

Conclusion:

Choosing the right air springs for your truck is crucial to ensure optimum performance, ride quality, and safety. Consider factors such as weight capacity, ride quality, durability, and compatibility when making your selection. By taking the time to research and choose the right air springs, you can enjoy a smoother and more comfortable ride in your truck.

Tools and materials needed for installation

Tools and Materials Needed for Installation

When it comes to installing truck air springs, having the right tools and materials is essential for a successful installation. Whether you are a DIY enthusiast or a professional truck owner, here is a comprehensive list of items you will need:

| Tools | Materials |

|---|---|

|

|

Having a socket set and a wrench set is crucial for removing the existing suspension components and installing the new air springs. Pliers and screwdrivers will come in handy for various tasks during the installation process. Wire cutters are necessary for removing any old wiring if needed. A tape measure is useful for ensuring precise measurements.

In addition to the tools, you will also need specific materials for the installation. The most important item is the air springs kit itself, which contains the air springs, bellows, and other necessary components. An air compressor is vital for inflating the air springs and adjusting the pressure. An air hose and Teflon tape are required to connect the air compressor to the air springs.

Mounting brackets and mounting hardware are essential for securely attaching the air springs to your truck’s chassis. These components ensure that the air springs remain in place and handle the weight of your truck effectively. Lastly, electrical connectors may be needed if your air springs have electronic controls for adjusting the suspension.

In conclusion, before starting the installation process, make sure you have all the necessary tools and materials. Having a well-equipped toolbox will ensure a smooth and hassle-free installation of your truck air springs. With the right tools in hand, you’ll be able to enjoy the benefits of improved suspension and ride quality in no time.

Step-by-step guide to installing truck air springs

Installing truck air springs is an important step in improving the performance and safety of your truck. Air springs, also known as air bags or helper springs, are a type of suspension system that can be added to your truck to provide additional support and stability. Whether you are towing heavy loads or simply looking to improve your truck’s ride quality, installing air springs can make a significant difference. In this step-by-step guide, we will walk you through the process of installing truck air springs, from gathering the necessary tools and materials to completing the installation.

Step 1: Gather the Tools and Materials

Before you begin the installation process, you will need to gather the necessary tools and materials. Here is a list of what you will typically need for installing truck air springs:

| Tools | Materials |

|---|---|

| Socket wrench set | Air springs kit |

| Torque wrench | Air compressor |

| Wire cutters | Air line tubing |

| Drill | Air fittings |

| Phillips screwdriver | Mounting hardware |

Step 2: Prepare Your Truck

Once you have gathered all the necessary tools and materials, it’s time to prepare your truck for the installation. Start by parking the truck on a flat and level surface. Engage the parking brake and ensure the truck is secure. If your truck is equipped with an air suspension system, be sure to release the air pressure before proceeding with the installation. This can typically be done by opening the air valve or switching off the air compressor.

Step 3: Remove the Old Suspension Components

Next, you will need to remove any old suspension components that may interfere with the installation of the air springs. This can include coil springs, leaf springs, or any other type of suspension parts that occupy the same space as the air springs. Use the appropriate tools to carefully remove these components, following any manufacturer instructions or guidelines. It is important to work safely and cautiously during this step to avoid any damage to your truck.

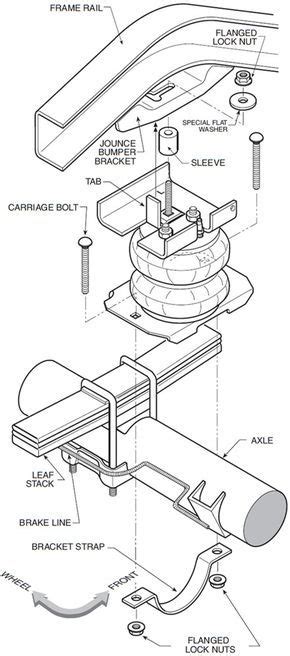

Step 4: Install the Air Springs

With the old suspension components removed, it’s time to install the new air springs. Begin by attaching the air springs to the mounting brackets or hardware provided in the kit. Ensure that the air springs are properly aligned and securely fastened. Once the air springs are in place, connect the air line tubing to the air springs using the appropriate fittings. Be sure to follow any specific instructions provided by the manufacturer for attaching the air line tubing.

Step 5: Connect the Air Compressor

After the air springs are securely installed, it’s time to connect the air compressor. The air compressor is responsible for supplying the air pressure needed to inflate and deflate the air springs as needed. Refer to the manufacturer’s instructions for the specific steps on connecting the air compressor to your truck’s electrical system and mounting it in a suitable location. Take care to properly route and secure the air line tubing from the air springs to the air compressor.

Step 6: Test and Adjust

Once the air springs and air compressor are installed, it’s important to test and adjust the system to ensure proper functionality. Start by turning on the air compressor and allowing it to build up the recommended air pressure. Check for any leaks or abnormal sounds during this process. Next, test the air springs by loading your truck with the desired weight and adjusting the air pressure as needed to achieve the desired ride height and level of support. Take the time to fine-tune the system to match your specific needs and preferences.

By following these step-by-step instructions, you can successfully install truck air springs and enhance the performance and safety of your truck. Remember to consult the manufacturer’s instructions and guidelines specific to your truck and air springs kit for any additional steps or considerations. Proper installation and maintenance of truck air springs are vital for maximizing their benefits and ensuring their longevity. Enjoy the improved ride quality and handling that comes with the installation of truck air springs!

Tips for proper maintenance and care

Tips for Proper Maintenance and Care

Proper maintenance and care are essential for ensuring the longevity and optimal performance of truck air springs. By following a few simple tips, you can maintain the integrity of your air springs and prevent unnecessary damages. Here are some valuable tips to keep in mind:

- Regular Inspection: Regularly inspect your truck air springs for any signs of wear or damage. Check for leaks, cracks, or punctures in the air springs and ensure that all mounting brackets and hardware are secure.

- Cleanliness: Keep the air springs clean by removing any dirt, mud, or debris that may accumulate on them. A clean surface helps to prevent corrosion and other issues.

- Tighten Loose Bolts: Ensure that all bolts and fasteners in the air spring system are properly tightened. Loose bolts can cause vibrations and impact the stability of the springs.

Additionally, it is crucial to follow the manufacturer’s guidelines for maintenance and care. Each brand and type of truck air spring may have specific instructions, so it is essential to refer to the user manual provided by the manufacturer.

| Task | Frequency | Description |

|---|---|---|

| Inspect for Signs of Wear | Every 3 months | Check for leaks, cracks, or damage. |

| Clean the Air Springs | As needed | Remove dirt, mud, and debris. |

| Tighten Bolts and Fasteners | Every 6 months | Ensure all bolts are securely tightened. |

By adhering to these maintenance tips and the manufacturer’s guidelines, you can extend the lifespan of your truck air springs and ensure they continue to function optimally. Neglecting proper maintenance can lead to expensive repairs or even failure of the air springs, compromising the safety and performance of your truck. Remember, prevention and regular care are key to avoiding issues and maintaining the longevity of your truck air springs.

Common troubleshooting issues and solutions

Truck air springs are an essential component of a truck’s suspension system, providing support and stability to the vehicle. However, like any other mechanical part, air springs can experience issues and require troubleshooting. In this blog post, we will discuss some common problems that truck owners may encounter with their air springs and provide solutions to fix them.

1. Leaking Air: One of the most common issues with truck air springs is air leakage. This can cause the suspension system to lose its ability to support the weight of the truck, resulting in a sagging or uneven ride. To fix this problem, it is important to first inspect the air springs for any visible damage or cracks. If no visible damage is found, the issue may be with the air fittings or valves. Check for loose connections and tighten them if needed. If the air springs continue to leak, it may be necessary to replace them.

2. Overinflated or Underinflated Air Springs: Another issue that truck owners may encounter is overinflated or underinflated air springs. Overinflated air springs can lead to a harsh and bumpy ride, while underinflated air springs can cause the truck to sag and affect the handling. To solve this problem, it is important to regularly check the air pressure in the springs using a pressure gauge. Refer to the manufacturer’s guidelines for the recommended pressure range and adjust accordingly.

3. Excessive Vibrations: Experiencing excessive vibrations while driving can be another troubleshooting issue with truck air springs. This can be caused by worn-out or damaged air springs, worn-out shock absorbers, or improper installation. To address this problem, inspect the air springs and shock absorbers for any signs of wear or damage. Replace any worn-out components and ensure proper installation. If the issue persists, it is recommended to consult with a professional mechanic or technician.

By addressing these common troubleshooting issues with truck air springs, you can ensure a smoother and safer ride for your truck. Regular maintenance, such as checking air pressure and inspecting for damages, can help identify and prevent potential problems. Remember to use the appropriate tools and materials for installation and follow a step-by-step guide if you are installing air springs yourself. Additionally, consider investing in reputable brands and quality products for better performance and durability.

Recommended brands and products for truck air springs

When it comes to truck air springs, choosing the right brand and product is crucial for optimal performance and safety. With so many options available in the market, it can be overwhelming to make a decision. To help you make an informed choice, we have compiled a list of recommended brands and products that are known for their reliability, durability, and functionality.

Listed below are some of the top brands and products that have received positive feedback from truck owners and professionals:

| Brand | Product |

|---|---|

| Firestone | Ride-Rite Air Helper Spring Kit |

| Air Lift | LoadLifter 5000 Ultimate Air Springs |

| Bilstein | B6 4600 Series Air Shock Absorbers |

| RideTech | ShockWave Air Suspension System |

| Arnott | Air Suspension Compressor |

These brands and products have consistently proven their quality and performance in various truck models and applications. They offer a range of features such as adjustable air pressure, enhanced load support, improved ride comfort, and easy installation.

Before making a purchase, it is important to consider factors such as the specific requirements of your truck, your budget, and any additional features or accessories you may need. Researching customer reviews and seeking recommendations from experienced truck owners or mechanics can also provide valuable insights.

In conclusion, investing in reliable and high-quality brands and products for your truck air springs is essential for a smooth and comfortable ride. The recommended brands and products mentioned above are renowned for their performance and durability, making them a solid choice for truck owners looking to upgrade their suspension systems. Remember to consider your specific needs and preferences before making a final decision.