If you’re a car enthusiast or just someone who wants to understand more about the role and function of shock absorbers in your vehicle, you’ve come to the right place. In this comprehensive guide, we’ll cover everything you need to know about shock absorbers, from their basic definition and working principles to the different types available and the importance of maintaining their optimal condition. We’ll also walk you through how to identify signs of worn-out shock absorbers, test their performance, and replace them with a step-by-step guide. Additionally, we’ll discuss common mistakes to avoid when replacing shock absorbers, upgrading to performance shock absorbers, and maintenance tips for prolonging their lifespan. So, let’s dive into the world of shock absorbers and explore the essential information you need to keep your vehicle running smoothly.

What Are Shock Absorbers?

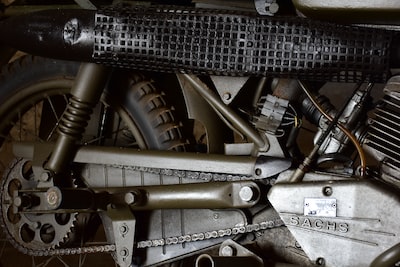

Shock absorbers, also known as dampers, are an essential component of a vehicle’s suspension system. They play a crucial role in ensuring a smooth and comfortable ride by absorbing and controlling the impact of road irregularities. In simple terms, shock absorbers are designed to dampen the movement of the suspension springs, thereby reducing the bounce and preventing excessive oscillation of the vehicle. They form a vital link between the wheels and the chassis, providing stability, control, and improved handling.

There are several types of shock absorbers available in the market, each designed for specific purposes and vehicle applications. The most common type is the hydraulic shock absorber, which utilizes a piston and fluid to absorb the energy from the springs. Gas-filled shock absorbers, on the other hand, incorporate pressurized gas to enhance their damping capabilities. Another type is the adjustable shock absorber, which allows for manual or electronic adjustment of damping force to suit different driving conditions.

The importance of shock absorbers cannot be overstated. Apart from providing a comfortable ride, they also play a critical role in ensuring the safety of the vehicle and its occupants. When shock absorbers are worn-out or faulty, the vehicle’s stability and handling can be severely compromised, leading to increased stopping distances, reduced traction, and poor maneuverability. Therefore, it is crucial to routinely inspect and replace worn-out shock absorbers to maintain the optimal performance and safety of the vehicle.

How Do Shock Absorbers Work?

Shock absorbers are an important component of a vehicle’s suspension system. As the name suggests, their main function is to absorb shocks or impacts that occur while driving. The shock absorbers play a crucial role in maintaining stability, control, and comfort while driving.

So, how do shock absorbers work? To understand this, we need to know a little bit about the suspension system. The suspension system of a vehicle consists of several components, including springs, dampers, and control arms. While the springs provide support and absorb vertical movement, the shock absorbers take care of dampening the oscillations caused by these movements.

When the suspension system encounters bumps, potholes, or any other disturbances on the road, the springs compress and release, causing the vehicle to bounce. This bouncing motion can not only make the ride uncomfortable but also affect the vehicle’s handling and stability. This is where the shock absorbers come into play.

- Shock absorbers are hydraulic devices that are designed to dampen the spring oscillations by converting kinetic energy into thermal energy, dissipating it into the surrounding air. They consist of a piston that moves through a cylinder filled with hydraulic fluid.

- When the vehicle encounters a bump, the piston is forced up or down, compressing the hydraulic fluid inside the cylinder. This compression creates resistance, which slows down the movement of the piston, controlling the spring’s oscillations.

- The hydraulic fluid passes through small channels or valves inside the shock absorbers. These channels or valves regulate the flow of the fluid to control the speed at which the piston moves, ensuring optimal damping.

- The shock absorbers also help maintain constant tire contact with the road surface, known as tire traction. They achieve this by preventing excessive vertical movement of the wheels, ensuring better grip and stability when driving over uneven terrains.

In summary, shock absorbers work by converting the kinetic energy generated by the springs into thermal energy through the compression and expansion of hydraulic fluid. They play a crucial role in controlling the vehicle’s movements, providing a smooth and comfortable ride, and improving handling and stability.

Types Of Shock Absorbers

A shock absorber is a crucial component of a vehicle’s suspension system, responsible for absorbing and dampening the shock caused by rough roads or sudden bumps. There are several types of shock absorbers available in the market, each designed to serve a specific purpose and cater to different vehicles and driving styles.

1. Conventional Shock Absorbers: Also known as hydraulic shock absorbers, these are the most common type found in vehicles. They use hydraulic fluid to absorb the impact and convert the kinetic energy into heat energy. When the vehicle encounters a bump, the piston inside the shock absorber moves up and down, pushing the hydraulic fluid through tiny orifices, which creates resistance and dampens the vibrations.

2. Gas Shock Absorbers: Gas shock absorbers, as the name suggests, utilize a combination of hydraulic fluid and pressurized gas to dampen the shocks. These shocks contain a small amount of nitrogen gas, which helps maintain the pressure within the shock absorber. The gas prevents the hydraulic fluid from foaming, ensuring consistent performance even during intense driving conditions.

3. Adjustable Shock Absorbers: These shock absorbers allow the driver to adjust the damping force according to their preference or driving conditions. They usually come with multiple settings or a knob that allows the driver to make adjustments on the go. This feature is particularly beneficial for performance enthusiasts who want to fine-tune their vehicle’s suspension for different tracks or terrains.

| Shock Absorber Type | Advantages | Disadvantages |

| Conventional | Cost-effective, widely available | Less control, prone to overheating under extreme conditions |

| Gas | Better damping performance, reduced foaming | Relatively expensive, limited adjustability |

| Adjustable | Customizable damping, improves handling | Higher cost, complex setup |

When it comes to selecting the right shock absorbers for your vehicle, you must consider factors such as driving style, road conditions, and budget. It is advisable to consult with a professional or an expert in the field to ensure you choose the most suitable shock absorbers for your specific requirements. Remember, the type of shock absorbers you opt for can greatly impact your vehicle’s ride comfort, handling, and overall performance.

The Importance Of Shock Absorbers

Shock absorbers are a crucial component of a vehicle’s suspension system. They play a vital role in ensuring a smooth and comfortable ride, as well as maintaining control and stability while driving. Shock absorbers work by dampening the impact of bumps, potholes, and other irregularities in the road surface. Without them, the vehicle would bounce and oscillate uncontrollably, making it difficult for the driver to maintain proper control.

The role of shock absorbers goes beyond just providing a comfortable ride. They also play a significant role in ensuring the safety of the vehicle and its occupants. By absorbing the energy generated from road imperfections, shock absorbers prevent excessive movement of the vehicle’s suspension system. This helps to keep the tires in contact with the road at all times, improving traction and reducing the risk of skidding or sliding, especially during sudden maneuvers or emergency braking.

In addition to improving ride comfort and safety, shock absorbers also contribute to the overall durability and lifespan of other suspension components. By absorbing the energy of impact and preventing excessive movement, they help protect other crucial parts such as the springs, struts, and tire sidewalls. This reduces the risk of premature wear and damage to these components, thereby extending their lifespan and reducing the need for costly repairs or replacements.

Signs Of Worn-Out Shock Absorbers

Shock absorbers are an integral component of a vehicle’s suspension system. They help to provide a smooth and comfortable ride by absorbing and dampening the impact of bumps and vibrations on the road. However, over time, shock absorbers can deteriorate and become less effective, compromising the vehicle’s handling and safety. There are several signs that indicate worn-out shock absorbers, and it is essential to be aware of them to ensure your safety on the road.

1. Uneven Tire Wear: One of the prominent signs of worn-out shock absorbers is uneven tire wear. When the shocks are no longer functioning correctly, the tires may not make proper contact with the road surface, resulting in irregular tread wear on the tires. You may notice bald spots or excessive wear on certain areas of the tire, which can affect both handling and braking performance.

2. Excessive Bouncing: Worn-out shock absorbers often lead to a bouncy ride. If you notice that your vehicle continues to bounce excessively after driving over bumps or dips in the road, it could be a clear indication of deteriorated shocks. The bouncing sensation is caused by the absence of proper damping, which should stabilize the vehicle’s suspension quickly.

3. Longer Braking Distance: Another sign of worn-out shock absorbers is an increase in braking distance. When shocks are no longer able to effectively control the up-and-down motion of the vehicle’s suspension, weight transfer during braking becomes less predictable. This can result in a longer stopping distance, potentially jeopardizing your safety in emergency situations.

4. Poor Handling and Control: Worn-out shock absorbers can significantly affect the vehicle’s handling and control. You may experience excessive body roll during cornering, reduced stability at higher speeds, or a general lack of responsiveness in steering. These symptoms can make your vehicle more challenging to control, increasing the risk of accidents.

5. Noisy Suspension: If you hear unusual noises coming from your vehicle’s suspension, such as knocking or rattling sounds, it could be a sign of worn-out shock absorbers. As the shocks deteriorate, they may develop internal damage or lose their ability to absorb vibrations properly, resulting in noise during driving.

It is crucial to address these signs promptly and have your shock absorbers inspected and replaced if necessary. Ignoring worn-out shock absorbers can lead to further damage to your vehicle’s suspension system and compromise your safety on the road. Regular inspection and maintenance of your shock absorbers can help prolong their lifespan and ensure a smooth and comfortable driving experience.

How To Test Shock Absorbers

Shock absorbers are an important component of a vehicle’s suspension system. They play a crucial role in ensuring a smooth and comfortable ride by absorbing the impact of bumps and vibrations on the road. Over time, shock absorbers can wear out and lose their effectiveness, which can negatively affect the handling and stability of the vehicle. Hence, it is necessary to test shock absorbers regularly to identify any issues and ensure optimal performance.

One of the simplest ways to test shock absorbers is through a visual inspection. Start by examining the shocks for any leaks or signs of damage. A typical sign of a leaky shock absorber is oil dripping down from the sealing area. If you notice any leaks or damage, it is a clear indication that the shock absorbers need to be replaced. Additionally, check for any loose or broken mounting brackets or bushings, as these can also affect the performance of the shocks.

Another method to test shock absorbers is the bounce test. To perform this test, push down on each corner of the vehicle and release quickly. Observe how the vehicle reacts after releasing it. Ideally, the vehicle should bounce back up once and come to a rest. If the vehicle continues to bounce or oscillate multiple times, it indicates that the shock absorbers are worn out and need to be replaced.

| Signs of Worn-Out Shock Absorbers: | How to Test Shock Absorbers: |

|---|---|

| 1. Leaking shocks | 1. Visual inspection for leaks and damage |

| 2. Excessive bouncing or oscillation | 2. Perform the bounce test |

| 3. Uncomfortable ride | 3. Conduct a road test for comfort and stability |

| 4. Strange noises from the suspension | 4. Listen for unusual noises during the road test |

In conclusion, regularly testing the shock absorbers is crucial for maintaining the optimal performance and safety of a vehicle. By visually inspecting for leaks and damage, performing a bounce test, and conducting a road test, you can effectively evaluate the condition of the shock absorbers. If any signs of wear or failure are detected, it is recommended to replace the shock absorbers promptly to ensure a smooth and comfortable ride.

Replacing Shock Absorbers: A Step-By-Step Guide

Shock absorbers are an essential component of a vehicle’s suspension system. They play a vital role in providing a smooth and comfortable ride by absorbing the impact of bumps and potholes on the road. Over time, shock absorbers can wear out due to constant use and exposure to harsh driving conditions. When this happens, it is crucial to replace them to ensure optimal vehicle performance and safety.

Before replacing shock absorbers, it is important to gather all the necessary tools and equipment. Some common tools required for this task include a jack, jack stands, wrenches, and a socket set. Additionally, it is recommended to have a service manual specific to your vehicle model on hand for reference.

The first step in replacing shock absorbers is to safely lift the vehicle off the ground using a jack. Ensure that the vehicle is securely supported on jack stands before proceeding with any work underneath. Once the vehicle is lifted, locate the shock absorbers, which are typically mounted near each wheel. Depending on the vehicle make and model, there may be multiple shock absorbers to be replaced.

| Step | Description |

|---|---|

| 1 | Remove the old shock absorbers by loosening the bolts that secure them to the suspension system. |

| 2 | Compare the old and new shock absorbers to ensure they are identical in size and specifications. |

| 3 | Install the new shock absorber by aligning it with the mounting points on the suspension system and tighten the bolts securely. |

After the new shock absorbers are installed, carefully lower the vehicle back onto the ground and remove the jack stands. Test the vehicle by taking it for a short drive to ensure that the new shock absorbers are functioning correctly. Pay attention to any unusual noises, vibrations, or handling issues, which may indicate an improper installation or faulty shock absorbers. If any issues arise, it is recommended to seek professional assistance to address the problem promptly.

Regular maintenance and inspection of shock absorbers are essential for prolonging their lifespan and ensuring optimal performance. It is advisable to inspect shock absorbers for signs of wear or leakage periodically. Additionally, following the manufacturer’s recommended service schedule and guidelines will help maintain the suspension system’s performance and overall safety of the vehicle.

Common Mistakes To Avoid When Replacing Shock Absorbers

Replacing shock absorbers is an essential task to ensure a smooth and stable ride in your vehicle. However, it is important to avoid some common mistakes that people often make while replacing shock absorbers. These mistakes can lead to poor performance, reduced safety, and even damage to the suspension system. In this blog post, we will discuss some of the most common mistakes to avoid when replacing shock absorbers, and provide you with some valuable tips to ensure a successful replacement process.

One of the most common mistakes people make is not considering the quality of the shock absorbers they are purchasing. It is important to invest in high-quality shock absorbers that are specifically designed for your vehicle make and model. Using cheap and generic shock absorbers may seem like a cost-effective option initially, but they are likely to wear out quickly and fail to provide the desired performance. It is always recommended to purchase shock absorbers from reputable manufacturers or dealers to ensure longevity and optimal performance.

Another common mistake is not replacing the shock absorbers in pairs. When one shock absorber becomes worn out or damaged, it is essential to replace both shock absorbers on the same axle. This is because the remaining old shock absorber is likely to have similar wear and tear, and mismatched shock absorbers can lead to uneven suspension behavior and compromised handling. Replacing shock absorbers in pairs ensures that the vehicle maintains consistent and balanced performance on all wheels.

| Common Mistakes To Avoid | Why it is important |

|---|---|

| Using low-quality shock absorbers | Investing in high-quality shock absorbers ensures longevity and optimal performance. |

| Not replacing shock absorbers in pairs | Replacing shock absorbers in pairs ensures consistent and balanced performance on all wheels. |

Furthermore, failing to properly inspect other components of the suspension system during shock absorber replacement is another common mistake to avoid. It is crucial to check for any signs of wear or damage in the suspension springs, mounts, and bushings. Neglecting these components can lead to premature failure of the newly replaced shock absorbers and result in a bumpy and uncomfortable ride. It is recommended to visually inspect and test the condition of all related suspension components and replace any worn-out or damaged parts before installing new shock absorbers.

In conclusion, replacing shock absorbers is a task that requires attention to detail and careful execution. By avoiding common mistakes such as using low-quality shock absorbers, not replacing shock absorbers in pairs, and neglecting other suspension components, you can ensure a successful shock absorber replacement process. Following these tips will help maintain the performance, safety, and longevity of your vehicle’s suspension system, providing you with a smooth and comfortable ride for years to come.

Upgrading To Performance Shock Absorbers

Upgrading your shock absorbers to performance ones can greatly enhance your vehicle’s handling, stability, and overall driving experience. While standard shock absorbers are designed to provide a comfortable ride and absorb the impact of bumps and potholes, performance shock absorbers are engineered to provide firmer and more precise suspension control, making them an ideal choice for driving enthusiasts and those seeking improved performance.

Performance shock absorbers, also known as sport or high-performance shocks, offer a range of benefits over their standard counterparts. They are specifically designed to provide better control and responsiveness, resulting in improved handling and cornering. These shocks are usually firmer and stiffer, which reduces body roll and allows for quicker steering response.

In addition to enhanced handling, upgrading to performance shock absorbers can also improve braking performance. By providing more consistent and controlled weight transfer during braking, these shocks help to reduce nosedive and maintain better traction, resulting in shorter stopping distances and improved overall safety.

| Twin-Tube Shocks: | These shocks consist of two tubes: an inner tube known as the working cylinder, and an outer tube known as the reserve tube. Twin-tube shocks are typically more affordable and offer good all-around performance. |

| Monotube Shocks: | Monotube shocks have a single tube design, with the working cylinder and the reserve chamber housed within the same tube. They provide better heat dissipation, improved ride quality, and greater durability. |

| Coilover Shocks: | Coilover shocks combine a shock absorber and a coil spring into one unit. They allow for customizable ride height, damping, and spring rates, making them popular in the performance and racing communities. |

Maintenance Tips For Prolonging Shock Absorber Lifespan

Shock absorbers play a crucial role in a vehicle’s suspension system. They are designed to absorb and dampen the impact caused by bumps, potholes, and uneven road surfaces. Over time, shock absorbers can wear out, leading to a decrease in performance and potential safety hazards. To ensure a longer lifespan for your shock absorbers and maintain optimal performance, here are some maintenance tips to keep in mind.

Regular Inspections: It is essential to inspect your shock absorbers regularly, especially if you frequently drive on rough terrains or off-road. Look out for signs of damage such as leaks, dents, or excessive rust. These signs indicate that the shock absorbers may need to be replaced. Additionally, inspect the mounting brackets and bushings for any wear and tear.

Cleaning: Keeping your shock absorbers clean can help prevent the buildup of dirt and debris, which can affect their performance. Use a mild soap and water solution to clean them, and be sure to rinse thoroughly. Avoid using harsh chemicals or abrasive materials, as they can damage the shock absorbers’ surfaces.

Proper Lubrication: Lubrication is crucial for the smooth operation of shock absorbers. Apply a high-quality lubricant to the piston rod and other moving parts. This helps reduce friction and ensures that the shock absorbers function effectively. Be careful not to use excessive amounts of lubricant, as this can attract dirt and debris.

- Driving Habits: Your driving habits can significantly impact the lifespan of your shock absorbers. Avoid harsh braking, sudden acceleration, and rough driving on uneven surfaces. These actions can put excessive strain on the shock absorbers, causing them to wear out more quickly.

- Load Management: Overloading your vehicle can place extra stress on the shock absorbers. It is important to follow the manufacturer’s recommendations for maximum load capacity. Distribute the weight evenly and avoid carrying unnecessary heavy items.

| Do: | Don’t: |

|---|---|

| Inspect shock absorbers regularly | Ignore signs of wear and damage |

| Clean shock absorbers with a mild soap solution | Use harsh chemicals or abrasive materials for cleaning |

| Lubricate moving parts with a high-quality lubricant | Use excessive amounts of lubricant |

| Drive smoothly and avoid rough driving | Engage in harsh braking and sudden acceleration |

| Manage the vehicle’s load properly | Overload the vehicle with excessive weight |

By following these maintenance tips, you can significantly prolong the lifespan of your shock absorbers and ensure a smooth and safe driving experience. Remember that regular inspections, cleaning, lubrication, and responsible driving habits are key to maximizing the performance and durability of shock absorbers.