Introduction:

In the world of trucks and heavy-duty vehicles, maintenance is key to ensuring their optimal performance and longevity. One vital component that often gets overlooked is the semi truck air dryer. This humble yet crucial device plays a significant role in maintaining the truck’s braking system and overall safety on the road. In this blog post, we will delve into the world of semi truck air dryers, exploring their importance, how they work, common problems, troubleshooting steps, and the benefits of regular maintenance. Additionally, we will guide you on how to choose the right air dryer for your semi truck and provide step-by-step instructions for replacing it when needed. Prepare to level up your truck’s maintenance game!

What is a semi truck air dryer?

A semi truck air dryer is an essential component of the braking system in a commercial vehicle. It plays a crucial role in maintaining the efficiency and effectiveness of the overall braking system. The air dryer is responsible for removing moisture and contaminants from the compressed air used in the brake system, ensuring optimal performance and preventing potential damages.

Importance of maintaining the air dryer:

How does a semi truck air dryer work?

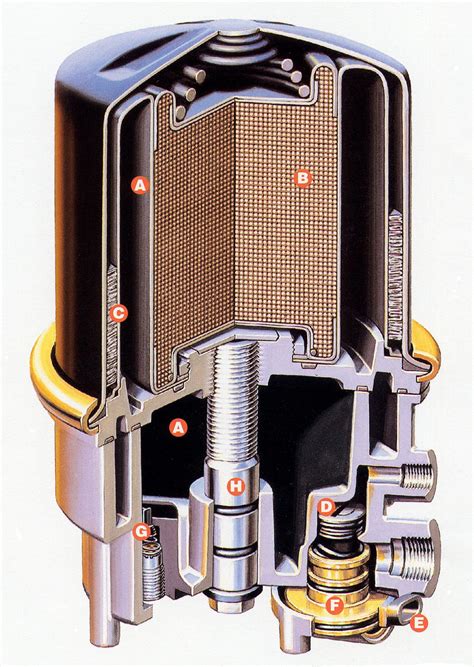

The air dryer operates using a desiccant material, typically in the form of small beads, which adsorb moisture from the compressed air. The compressed air from the air compressor enters the air dryer, where it passes through the desiccant material. The desiccant material traps and removes the moisture, ensuring dry air flows into the brake system. The air dryer also includes various valves and filters to control the flow of air and remove contaminants.

Overall, the air dryer plays a vital role in maintaining the safety, efficiency, and longevity of a semi truck’s braking system. Regular maintenance, inspection, and timely replacement of the air dryer are crucial to ensure optimal performance and prevent potential issues.

Importance of maintaining the air dryer

The air dryer in a semi truck is an integral part of the braking system. It plays a crucial role in removing moisture from the compressed air to prevent any potential damage to the system. Despite its significance, the air dryer is often overlooked and neglected when it comes to maintenance. However, maintaining the air dryer is of utmost importance to ensure the proper functioning of the braking system and overall safety on the road.

Regular maintenance of the air dryer is necessary to prevent the accumulation of moisture and contaminants. Moisture can degrade the quality of the brake air, leading to decreased braking efficiency and potential brake failure. Moreover, the presence of contaminants such as oil, dirt, and debris can clog the air dryer components, compromising its performance. Therefore, it is essential to schedule regular maintenance to clean and inspect the air dryer to ensure its optimum functioning.

One of the ways to maintain the air dryer is by regularly draining the moisture collected in the system. This can be done by following a simple procedure of opening the drain valve and letting the moisture escape. It is recommended to perform this task every month or as per the manufacturer’s guidelines. Additionally, inspecting the air dryer for any signs of leaks, damaged components, or excessive wear is crucial. Any necessary repairs or replacements should be promptly addressed to avoid further damage.

Another important aspect of air dryer maintenance is keeping a check on the desiccant cartridge. The desiccant cartridge is responsible for absorbing moisture from the compressed air. Over time, the desiccant may become saturated and lose its effectiveness. Therefore, it is essential to monitor the desiccant cartridge and replace it when necessary. Regularly inspecting and replacing the desiccant cartridge will help in ensuring optimal moisture removal and preventing moisture-related issues.

Proper maintenance of the air dryer not only safeguards the braking system but also extends the overall lifespan of the components. Neglecting the air dryer can lead to costly repairs and potential downtime. By prioritizing the maintenance of the air dryer, truck owners and operators can avoid unnecessary expenses and ensure the safety of both their vehicle and themselves.

How does a semi truck air dryer work?

A semi truck air dryer is an important component of the vehicle’s air brake system. It is responsible for removing moisture and contaminants from the compressed air before it enters the brake system. This ensures that the brake system operates effectively and efficiently, reducing the risk of brake failure and ensuring the safety of the driver and others on the road.

There are three main components that make up the semi truck air dryer: the desiccant cartridge, the purge valve, and the check valve. The desiccant cartridge is filled with a moisture-absorbing material called desiccant. As the compressed air flows through the cartridge, the desiccant removes any moisture present in the air, preventing it from entering the brake system.

The purge valve is responsible for releasing any accumulated moisture from the desiccant cartridge. It does this by opening a pathway for the moisture-laden air to escape, allowing fresh dry air to enter the cartridge. The purge valve is controlled by a dryer controller, which senses the moisture level in the cartridge and opens or closes the purge valve accordingly.

The check valve is a one-way valve that prevents air from flowing back into the desiccant cartridge once it has been expelled. This ensures that the compressed air only flows in one direction, through the desiccant cartridge and into the brake system.

Overall, the semi truck air dryer works by filtering out moisture and contaminants from the compressed air, ensuring that only clean, dry air enters the brake system. This helps to prevent corrosion, rust, and other damage to the brake components, as well as maintaining proper brake performance. Regular maintenance and inspections of the air dryer are essential to ensure its proper functioning and to prevent potential issues with the brake system.

Signs of a faulty air dryer

If you own a semi truck, it is important to understand the various components that make up its air system. One crucial component is the air dryer. The air dryer is responsible for removing moisture and contaminants from the compressed air, ensuring that the air system functions properly. However, like any other part of a vehicle, the air dryer can develop faults over time. It is essential to be aware of the signs that indicate a faulty air dryer, as addressing the issue promptly can prevent further damage and potentially costly repairs.

1. Wet air system: One of the most obvious signs of a faulty air dryer is a wet air system. If you notice excessive moisture in your air system, it could be an indication that the air dryer is not effectively removing the moisture. This can result in decreased efficiency and performance of various air-powered components in your semi truck.

2. Excessive air pressure: Another sign of a faulty air dryer is when there is a significant increase in air pressure. If the air dryer is not functioning correctly, it may not be able to regulate the pressure properly, leading to abnormally high air pressure levels. This can cause damage to other air system components and potentially result in system failure if not addressed promptly.

3. Contaminated air: A faulty air dryer may also allow contaminants, such as oil or dirt, to pass through the system and into your air-powered components. Contaminated air can adversely affect the performance and lifespan of these components. If you notice a decrease in the performance of air-powered systems or frequent issues with valves sticking, it may be due to a faulty air dryer.

Steps to troubleshoot air dryer issues

When it comes to maintaining the air dryer in your semi truck, it is important to be aware of any potential issues that may arise. Troubleshooting air dryer issues can help prevent further damage and ensure optimal performance. By following a few simple steps, you can identify and resolve common problems with your air dryer.

1. Check for air leaks: One of the first steps in troubleshooting air dryer issues is to check for any air leaks. Start by inspecting the air lines and connections for any signs of leakage. Use a soapy water solution to identify any escaping air. If you find any leaks, tighten the connections or replace the damaged parts.

2. Inspect the desiccant cartridge: The desiccant cartridge plays a crucial role in removing moisture from the air system. Over time, it can become saturated and lose its effectiveness. Inspect the desiccant cartridge for any signs of moisture or contamination. If necessary, replace the cartridge with a new one to ensure proper functioning of the air dryer.

3. Check the purge valve: The purge valve is responsible for releasing moisture and contaminants from the air dryer. If the valve becomes stuck or damaged, it may not function properly, leading to air dryer issues. Inspect the purge valve for any signs of blockage or damage. Clean or replace the valve if needed.

Benefits of regular air dryer maintenance

Regular air dryer maintenance is crucial for the efficient operation of a semi truck. Proper maintenance not only extends the lifespan of the air dryer but also enhances safety on the road. By performing regular maintenance, truck drivers can prevent major malfunctions and reduce downtime, leading to cost savings in the long run.

One of the key benefits of regular air dryer maintenance is ensuring the removal of moisture and contaminants from the air system. The air dryer plays a crucial role in removing moisture that can cause rust and corrosion in the air tanks, valves, and brake system components. By keeping the air system clean and dry, regular maintenance prevents the formation of ice in the brake lines during cold weather conditions, improving the reliability and effectiveness of the braking system.

Proactive air dryer maintenance also helps to identify potential issues before they escalate into major problems. During maintenance checks, truck drivers or technicians can inspect the air dryer and its components for any signs of wear and tear, leaks, or damaged parts. They can also clean or replace the desiccant cartridge, which is responsible for absorbing moisture. By addressing these issues early on, they can prevent the air dryer from becoming faulty or ineffective, saving both time and money.

Common air dryer problems and solutions

Common Air Dryer Problems and Solutions

Air dryers play a vital role in the proper functioning of semi trucks. These mechanisms are responsible for removing moisture from the compressed air system in order to prevent rust, corrosion, and other potential issues. However, like any other part of a vehicle, air dryers can encounter problems over time. In this article, we will discuss some of the most common air dryer problems faced by semi truck owners and provide practical solutions to resolve them.

1. Insufficient Moisture Removal: One of the frequent issues with air dryers is their inability to effectively eliminate moisture from the compressed air system. This can lead to water contamination in the air tanks and brake lines, resulting in decreased braking performance and potential safety hazards. To overcome this problem, it is important to regularly inspect and clean the desiccant cartridge or replace it if necessary. The desiccant cartridge absorbs moisture, and if it becomes saturated, it will no longer be able to perform its function properly.

2. Air Leakage: Another common problem faced by truck owners is air leakage from the air dryer. If there is a leak, the air dryer will not be able to maintain the required pressure in the compressed air system, which can adversely affect the braking system’s performance. To address this issue, it is essential to inspect the air dryer for any visible cracks or damage. Additionally, check the valves and connections for tightness and make sure they are properly sealed. If the air dryer or any component is found to be faulty, it is recommended to replace it with a new one to prevent further issues.

3. Excessive Noise or Vibrations: Unusual noises or vibrations coming from the air dryer can indicate underlying problems. These issues may be caused by a malfunctioning compressor, loose mounting brackets, or worn-out bearings. To troubleshoot this kind of problem, it is advised to visually inspect the air dryer for any loose or damaged parts. Tighten the mounting brackets securely and replace any worn-out components. If the issue persists, it is advisable to consult a professional mechanic for further assistance.

These are just a few of the common air dryer problems that semi truck owners might encounter. Regular maintenance and timely troubleshooting can help prevent these issues and ensure the optimal performance of the air dryer. By addressing these problems promptly and implementing the suggested solutions, drivers can stay safe on the road and extend the lifespan of their air dryers.

Choosing the right air dryer for your semi truck

Choosing the right air dryer for your semi truck is crucial in maintaining the performance and longevity of your vehicle. An air dryer is an essential component of the air brake system in a semi truck, responsible for removing moisture and contaminants from the compressed air before it enters the brake chambers. Without a properly functioning air dryer, moisture can accumulate, leading to brake system failures and reduced braking efficiency.

When selecting an air dryer for your semi truck, there are a few key factors to consider. Firstly, the capacity of the air dryer should match the air compressor’s output. It is important to ensure that the air dryer can handle the volume of compressed air produced by the compressor. Choosing an air dryer with a lower capacity may result in inadequate moisture removal.

Another factor to consider is the type of air dryer. There are two main types: desiccant and coalescing. Desiccant air dryers use a material called desiccant to absorb moisture from the compressed air, while coalescing air dryers use filters to remove moisture and contaminants. The choice between the two depends on the specific requirements of your semi truck and the operating conditions.

In addition to capacity and type, it is important to consider the maintenance requirements of the air dryer. Some air dryers require regular replacement of desiccant or filters, while others may have a self-regenerating feature. It is crucial to choose an air dryer that is compatible with your maintenance capabilities and schedule. Regular maintenance of the air dryer is essential to ensure its proper functioning and prevent any potential issues.

In conclusion, choosing the right air dryer for your semi truck is a decision that should not be taken lightly. Considering factors such as capacity, type, and maintenance requirements can help ensure that you select an air dryer that will effectively remove moisture and contaminants from the compressed air, contributing to the safety and performance of your vehicle. Properly maintaining the air dryer is equally important to extend its lifespan and prevent any potential problems. So, make an informed decision and choose the right air dryer for your semi truck!

How to replace an air dryer in a semi truck

If you own a semi truck, you probably know the importance of maintaining its various components to ensure optimal performance. One such crucial component is the air dryer, which plays a vital role in keeping the air system of your truck free from moisture and contaminants. Over time, air dryers can wear out or become faulty, requiring replacement. In this blog post, we will guide you through the step-by-step process of replacing an air dryer in a semi truck, ensuring that you can tackle this task with confidence.

Step 1: Gather the necessary tools and equipment

Step 2: Locate the air dryer

The air dryer is typically positioned near the air compressor, which is usually located on the engine or frame rail. It may be necessary to refer to your truck’s manual or consult a professional to accurately locate the air dryer in your specific truck model. Once you have identified the air dryer’s location, ensure that it is easily accessible for replacement.

Step 3: Drain the air system

Before replacing the air dryer, it is crucial to release any air pressure in the system to avoid potential hazards. Start by parking the truck on a level surface and engaging the parking brake. Then, turn off the engine and open the drain valve to release the pressure until no more air escapes. It is essential to wear protective gloves and eyewear during this step to ensure your safety.

Frequently Asked Questions

1. What is a semi truck air dryer?

A semi truck air dryer is a device that removes moisture and contaminants from the air supply system in a commercial truck. It helps prevent damage to various components in the truck’s air system and ensures proper braking and other functions.

2. Why is maintaining the air dryer in a semi truck important?

Maintaining the air dryer in a semi truck is important because it ensures the proper functioning of the vehicle’s air system. Regular maintenance helps prevent moisture and contaminants from causing damage to other components, reduces the risk of brake failure, and improves overall safety on the road.

3. How does a semi truck air dryer work?

A semi truck air dryer works by using a desiccant material, typically silica gel, to absorb moisture from the air passing through the system. The desiccant traps the moisture, allowing only clean, dry air to reach the rest of the air system. The trapped moisture is periodically released and expelled from the system.

4. What are some signs of a faulty air dryer in a semi truck?

Some signs of a faulty air dryer in a semi truck include reduced air pressure, longer brake application time, excessive water or oil in the air tanks, unusual brake noises, and frequent need for brake system repairs. These issues may indicate a malfunctioning air dryer that requires attention.

5. What are some steps to troubleshoot air dryer issues in a semi truck?

When troubleshooting air dryer issues in a semi truck, you can check for air leaks, inspect the desiccant cartridge, clean or replace the purge valve, check electrical connections, and ensure proper air dryer maintenance intervals. These steps can help identify and resolve common air dryer problems.

6. What are the benefits of regular air dryer maintenance in a semi truck?

The benefits of regular air dryer maintenance in a semi truck include improved brake performance, reduced risk of brake failure, extended lifespan of other air system components, enhanced overall safety on the road, and cost savings by avoiding costly repairs and breakdowns.

7. How do I choose the right air dryer for my semi truck?

To choose the right air dryer for your semi truck, consider factors such as the truck’s air system requirements, load capacity, operating conditions, and manufacturer recommendations. Consult with a trusted mechanic or dealer to determine the most suitable air dryer for your specific truck model.