If you are a truck driver or own a semi truck, you probably already know the importance of keeping your vehicle in top condition. One essential component of any semi truck’s air braking system is the air dryer. But what exactly is a semi truck air dryer, and why is it so important? In this blog post, we will explore the ins and outs of semi truck air dryers, including their function, the signs of a malfunctioning air dryer, and the steps to diagnose and replace a faulty one. We will also discuss the common causes of air dryer issues and the benefits of regular air dryer maintenance. By the end of this post, you’ll have a better understanding of the crucial role that an air dryer plays in your semi truck’s performance and longevity. So let’s dive in and learn all about semi truck air dryers!

What is a semi truck air dryer?

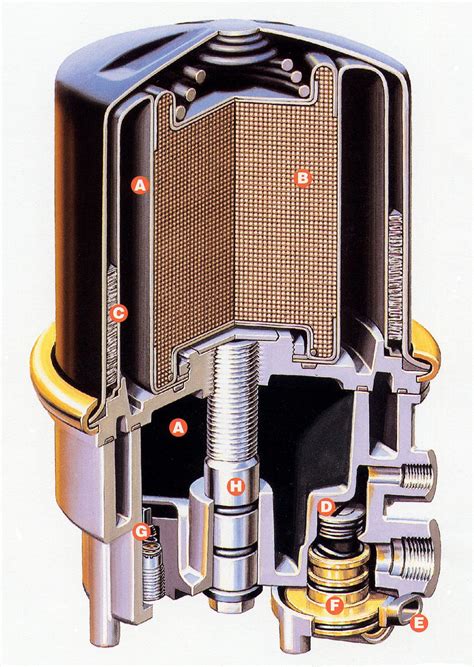

A semi truck air dryer is a crucial component of the air brake system, responsible for removing moisture and other contaminants from the compressed air that operates the brakes. It plays a vital role in ensuring the safety and efficiency of the braking system, preventing potential issues such as brake failure and corrosion. Without a properly functioning air dryer, the brakes may become less responsive and prone to malfunction, putting both the driver and other road users at risk.

One of the primary functions of a semi truck air dryer is to remove moisture from the air system. As air is compressed, it heats up and can hold more moisture. The air dryer uses desiccant materials to absorb the moisture, preventing it from entering the brake system where it could lead to corrosion and reduced braking performance. In addition to moisture, air dryers also filter out contaminants such as oil and dirt particles, further protecting the brake components from damage.

It is important to note that not all air dryers are created equal. There are different types of air dryer systems, including single cartridge and dual cartridge designs, each with its own set of features and benefits. It is essential for truck owners and operators to understand the specific type of air dryer used in their vehicles, as well as how to properly maintain and troubleshoot any potential issues that may arise.

In conclusion, a semi truck air dryer is a critical component of the air brake system, designed to remove moisture and contaminants from the compressed air to ensure the proper functioning of the brakes. Understanding the role and importance of the air dryer is essential for maintaining the safety and reliability of commercial trucks on the road.

Importance of a functioning air dryer

Having a functioning air dryer is crucial for the overall performance and safety of a semi truck. The air dryer plays a key role in removing moisture and contaminants from the compressed air system, preventing them from reaching the various components such as the air brake valves, brake chambers, and other pneumatic devices. This helps to prevent corrosion, rust, and other damage to the system, which can lead to costly repairs and potential safety hazards on the road.

Additionally, a properly functioning air dryer ensures that the air supply to the brake system is clean and dry, which is essential for reliable braking performance. Moisture and contaminants in the air brake system can cause brake fade, reduced braking efficiency, and potentially even brake failure, putting the driver and others on the road at risk.

Without a functioning air dryer, the air system can become compromised, leading to potential malfunctions and safety hazards. This can result in increased maintenance costs, downtime, and the need for emergency repairs, all of which can be avoided by ensuring that the air dryer is working properly at all times.

Overall, the importance of a functioning air dryer cannot be overstated, as it is essential for maintaining the safety, reliability, and efficiency of a semi truck’s air brake system.

Signs of a malfunctioning air dryer

One of the signs of a malfunctioning air dryer is when there is excessive moisture in the air brake system. This can cause the brakes to become less effective and can lead to safety hazards. If you notice that there is excess moisture in the air tanks, it may be a sign that the air dryer is not functioning properly.

Another sign of a malfunctioning air dryer is when the air compressor is constantly running. A properly functioning air dryer should regulate the air pressure in the system, and if the air compressor is constantly running, it could be a sign that the air dryer is not doing its job.

If you hear excessive air leakage, it may be a sign of a malfunctioning air dryer. This could indicate that there is a problem with the air dryer’s valves or seals, which could cause the system to lose air pressure and affect the braking capabilities of the semi truck.

Lastly, if the semi truck takes longer to build air pressure, it could be a sign of a malfunctioning air dryer. A properly functioning air dryer should help the system build air pressure efficiently, so if there are noticeable delays, it’s important to have the air dryer inspected and repaired.

Common causes of air dryer issues

One common cause of air dryer issues is a clogged desiccant cartridge. Over time, the desiccant material inside the cartridge can become saturated with moisture, reducing its effectiveness in removing water from the compressed air. This can lead to moisture buildup and potential damage to the air brake system.

Another cause of air dryer issues is a malfunctioning governor. The governor is responsible for regulating the air pressure within the air brake system, including the air dryer. If the governor fails, it can result in excessive cycling of the air dryer, leading to premature wear and eventual failure.

Additionally, air leaks in the air dryer system can cause issues. Whether it’s a leaky purge valve or a damaged air line, any leak can disrupt the proper function of the air dryer, allowing moisture to enter the brake system and compromising safety.

Lastly, lack of regular maintenance can also be a common cause of air dryer issues. Without proper servicing and inspection, parts can become worn or damaged, leading to inefficiency and potential failure of the air dryer.

How to diagnose air dryer problems

Diagnosing air dryer problems is essential for the proper maintenance of your vehicle’s air system. One common sign of a malfunctioning air dryer is when moisture residue is present in the air system. This can lead to corrosion and other damage to the system if not addressed promptly. Another important symptom to look out for is if there is a decrease in the amount of air pressure in the system, as this can indicate a problem with the air dryer’s functionality.

Additionally, if you notice that the air dryer is constantly releasing air, even when the system is not in use, this could be a clear indicator that there is an issue that needs to be resolved. Moreover, the presence of oil or water in the air tanks is another sign that there may be an issue with the air dryer. It is important to carefully inspect the air tanks and the area surrounding the air dryer for any signs of leaks, blockages, or damage.

In order to diagnose air dryer problems, it is crucial to properly test the air system for any abnormalities. Performing a visual inspection of the air dryer and the surrounding components can help identify any visible issues, such as leaks or damaged parts. Additionally, using an air pressure gauge to measure the air pressure in the system can help determine if there are any discrepancies that may indicate a problem with the air dryer.

Furthermore, consulting the manufacturer’s guidelines for the air dryer and conducting regular maintenance checks can help prevent potential issues from arising and keep the air system in optimal condition. By familiarizing yourself with the signs and symptoms of air dryer problems, you can ensure the longevity and efficiency of your vehicle’s air system.

Steps to replace an air dryer

Replacing an air dryer in a semi truck is a task that requires some technical knowledge and skills. The first step in the process is to locate the air dryer on the vehicle. This could be either in the engine bay or underneath the chassis. Once the air dryer is located, the next step is to depressurize the air system by draining the air tanks. This is an important safety precaution to prevent any accidental air release during the replacement process.

After depressurizing the air system, the next step is to remove the old air dryer from its mounting bracket. This may require the use of specific tools such as wrenches or sockets. It’s important to follow the manufacturer’s guidelines for removing the air dryer to avoid any damage to the surrounding components. Once the old air dryer is removed, the next step is to install the new air dryer in its place. Care should be taken to align the new air dryer properly and secure it to the mounting bracket according to the manufacturer’s specifications.

With the new air dryer in place, the next step is to reconnect the air lines to the dryer. It’s important to check for any signs of damage or wear on the air lines and replace them if necessary. Once the air lines are connected, the air system can be pressurized again by refilling the air tanks. This should be done carefully to ensure that there are no leaks in the system. Finally, the last step in the replacement process is to test the new air dryer to make sure it is functioning properly.

Following these basic steps can help ensure a successful replacement of the air dryer in a semi truck. However, if you are not confident in your ability to perform this task, it is recommended to seek the assistance of a qualified mechanic or technician.

Benefits of regular air dryer maintenance

Regular maintenance of your semi truck air dryer can offer numerous benefits, both in terms of safety and cost-effectiveness. By ensuring your air dryer is well-maintained, you can prevent potential malfunctions and breakdowns that can lead to expensive repairs and downtime.

Additionally, a properly maintained air dryer can help improve fuel efficiency and extend the lifespan of your braking system components, ultimately saving you money in the long run.

Furthermore, regular maintenance can contribute to safer driving conditions by reducing the risk of brake system failures and ensuring consistent performance of your vehicle’s air brake system.

Ultimately, the benefits of regular air dryer maintenance far outweigh the costs, making it a critical aspect of maintaining the safety and reliability of your semi truck.