When it comes to the suspension system of trucks, air springs play a crucial role in providing a smooth and comfortable ride. Understanding how air springs work and their importance in maintaining optimal performance is essential for every truck owner. Regular inspections are key to identifying signs of wear and tear, as they can affect the overall functionality of the air springs. In this blog post, we will discuss the common signs of air spring deterioration, provide a step-by-step guide to maintenance, and offer tips to extend their lifespan. Additionally, we will delve into choosing the right air spring replacement and the significance of proper inflation. For troubleshooting and professional maintenance services, we’ve got you covered.

Understanding Air Springs in Trucks

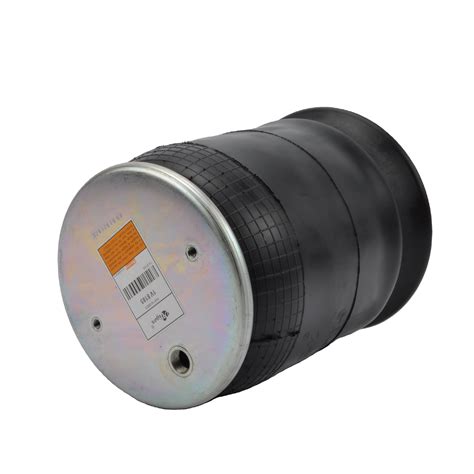

Air springs, also known as airbags, are an essential component of a truck’s suspension system. They are designed to provide a smooth and comfortable ride by absorbing the shocks and vibrations that occur while driving. These air-filled rubber bags are positioned between the axle and the frame of the truck, supporting the weight of the vehicle and its cargo. By adjusting the amount of air pressure inside the springs, the driver can control the height and firmness of the ride, resulting in improved stability and handling.

One of the key benefits of air springs in trucks is their ability to adapt to different load conditions. As the cargo weight changes, the air pressure can be adjusted accordingly to ensure optimal performance. This flexibility allows trucks to carry heavy loads without compromising on comfort and safety. Additionally, air springs help to distribute the weight evenly across the axles, reducing the strain on individual components and minimizing the risk of damage or premature wear.

To ensure the longevity and reliability of air springs, regular inspections and maintenance are crucial. Signs of wear and tear should be identified early on to prevent further damage and potential failures. Some common indications of air spring problems include sagging or uneven ride height, excessive bouncing or bouncing after hitting a bump, and air leaks. If any of these signs are observed, immediate attention and repair are necessary to avoid compromising the overall performance and safety of the truck.

In order to extend the lifespan of air springs, proper inflation is essential. Over or under inflation can lead to imbalances, causing uneven tire wear and reduced handling capabilities. It is recommended to follow the manufacturer’s guidelines for air pressure settings and regularly check the pressure using a reliable gauge. Regular inspections should also include a visual examination for any signs of leaks or damage to the air springs, as well as their mounting brackets and associated components.

While some truck owners may choose to replace air springs themselves, it is highly recommended to seek professional assistance for this task. Choosing the right air spring replacement is crucial in maintaining the performance and safety of the truck. Professionals have the expertise to identify the correct air spring model and ensure proper installation and alignment. They can also provide valuable advice on maintenance practices and troubleshooting common air spring problems.

In conclusion, understanding air springs in trucks is essential for truck owners and drivers. These components play a significant role in improving ride comfort, stability, and handling. Regular inspections, proper inflation, and timely maintenance are key to maximizing the lifespan and performance of air springs. Seeking professional assistance when needed ensures the correct selection and installation of air spring replacements, as well as access to expert advice and troubleshooting.

Importance of Regular Air Spring Inspections

Regular inspections of air springs in trucks are of utmost importance to ensure the performance and longevity of these crucial components. Air springs, also known as airbags or air bellows, play a significant role in supporting the vehicle’s weight, providing a smooth ride, and absorbing shocks and vibrations. To maintain their functionality and prevent unexpected failures, it is essential to conduct routine inspections and address any signs of wear and tear promptly.

One common sign of air spring wear and tear is visible damage, such as cracks or punctures in the rubber boot or the metal components. These damages can lead to air leaks and decrease the air spring’s ability to support the vehicle properly. Additionally, excessive bulging or sagging of the air spring may indicate internal damage or loss of pressure. It is crucial to visually inspect the air springs regularly to identify any visible signs of wear or damage.

Furthermore, regular inspections should also include checking the air spring’s pressure and inflation level. Proper inflation is crucial for the air spring’s performance and lifespan. Insufficient pressure can result in a rough and uncomfortable ride, decreased stability, and accelerated wear of other suspension components. On the other hand, overinflation can cause a harsh ride, reduced traction, and potential damage to the air spring or other parts of the suspension system.

- Inspect for visible damage: Regularly inspect the air springs for any visible signs of wear, such as cracks, punctures, or damage to the rubber or metal components.

- Check inflation level: Ensure that the air springs are properly inflated to the manufacturer’s recommended pressure. This helps maintain optimal performance and extends the lifespan of the air springs.

- Address issues promptly: If any signs of wear or damage are detected during the inspection, it is crucial to address them promptly. This may involve replacing the damaged air spring or seeking professional maintenance services.

A comprehensive inspection of the air springs should be conducted regularly, preferably as part of routine vehicle maintenance. This not only helps identify and address potential issues early on but also contributes to overall vehicle safety and performance. By prioritizing regular air spring inspections, truck owners and operators can ensure the longevity and optimal functionality of these critical components, reducing the risk of unexpected failures, costly repairs, and downtime.

Common Signs of Air Spring Wear and Tear

When it comes to trucks, air springs play a crucial role in providing a smooth and comfortable ride. However, like any other component, air springs are subject to wear and tear over time. It is important for truck owners and operators to be aware of the common signs of air spring wear and tear, as neglecting these signs can lead to further damage and potential safety hazards.

One of the most obvious signs of air spring wear and tear is a noticeable decrease in ride height. If you notice that your truck sits lower than usual or if it appears to be sagging in the rear, it could be a sign that your air springs are losing pressure or are damaged. This can affect the overall stability and handling of the truck, making it important to address the issue promptly.

Another sign to look out for is air leaks. Air springs can develop leaks over time, leading to a loss of pressure and reduced performance. If you hear a hissing or leaking sound coming from the air springs, it is a clear indication that there is a leak. Inspecting the air springs visually can also help identify any signs of air leakage such as cracks or holes in the rubber bellows.

In addition to decreased ride height and air leaks, abnormal vibrations or excessive bouncing can also indicate air spring wear and tear. If your truck feels unstable or if you experience a rough ride with increased road vibrations, it could be a result of damaged or worn-out air springs. These symptoms can be particularly noticeable when driving over bumps or uneven road surfaces.

- Decreased ride height: Truck sits lower or appears to sag

- Air leaks: Hissing or leaking sound, visual signs of leakage

- Abnormal vibrations or excessive bouncing: Unstable ride, rough ride with increased road vibrations

It is important to address these common signs of air spring wear and tear as soon as possible to ensure the safety and performance of your truck. Ignoring these signs can lead to further damage to other components, such as the suspension system, and can pose a risk to both the driver and the cargo being transported.

If you notice any of these signs, it is recommended to consult a professional for a thorough inspection and necessary repairs or replacements. Regular inspections and maintenance of air springs can also help prevent premature wear and extend their lifespan, ultimately saving you time and money in the long run.

| Common Signs of Air Spring Wear and Tear |

|---|

| Decreased ride height |

| Air leaks |

| Abnormal vibrations or excessive bouncing |

Step-by-Step Guide to Air Spring Maintenance

When it comes to maintaining the performance and longevity of your truck’s air springs, a step-by-step guide can be incredibly helpful. Air springs are a crucial component of the suspension system, providing support and cushioning to the vehicle. Regular maintenance ensures that the air springs are in optimal condition, preventing potential issues and ensuring a smooth ride. In this blog post, we will provide you with a comprehensive step-by-step guide to air spring maintenance, helping you keep your truck in top shape.

Before diving into the maintenance process, it’s important to understand how air springs work. Air springs, also known as airbags, are made of durable rubber and contain compressed air. They are typically installed between the frame and axle of a truck, providing support and absorbing shocks. The air pressure inside the air spring can be adjusted to suit the desired ride height and load capacity of the vehicle.

Now, let’s move on to the step-by-step guide for air spring maintenance:

- Inspect for Wear and Damage: Start by visually inspecting the air springs for any signs of wear and tear. Look for cracks, leaks, or other damage on the rubber surface. If you notice any issues, it’s crucial to address them promptly to avoid further damage.

- Clean the Air Springs: Use a mild soap and water solution to clean the air springs. Gently scrub the surface with a soft brush to remove any dirt or grime. Avoid using harsh chemicals or abrasive cleaners, as they can damage the rubber.

- Check Air Pressure: Measure the air pressure inside the air springs using a pressure gauge. Refer to the manufacturer’s guidelines or the vehicle’s manual to determine the recommended air pressure. Adjust the pressure as needed to ensure proper inflation.

In addition to these steps, it’s important to regularly check the overall suspension system for any issues. Inspect the connecting components and ensure they are secure and in good condition. If you encounter any problems during the maintenance process or notice abnormal behavior in the air springs, it’s advisable to seek professional assistance for further inspection and repair.

| Benefits of Regular Air Spring Maintenance |

|---|

| 1. Enhanced Performance: Regular maintenance ensures that the air springs are functioning optimally, providing a smoother and more controlled ride. |

| 2. Increased Lifespan: Proper maintenance helps prevent premature wear and tear, extending the lifespan of the air springs. |

| 3. Cost Savings: By avoiding major repairs or replacements, regular maintenance can save you money in the long run. |

| 4. Safety: Well-maintained air springs contribute to the overall safety of the vehicle, ensuring better handling and stability on the road. |

By following this step-by-step guide to air spring maintenance, you can effectively keep your truck’s suspension system in excellent condition. Remember to perform regular inspections, clean the air springs, and check the air pressure to ensure optimal performance and a comfortable ride. Invest time and effort into proper maintenance, and you’ll reap the benefits of improved longevity, performance, and safety for your truck.

Choosing the Right Air Spring Replacement

When it comes to maintaining the performance and longevity of your truck’s air suspension system, choosing the right air spring replacement is crucial. Air springs, also known as airbags, play a vital role in supporting and cushioning the weight of the vehicle, providing a smooth and comfortable ride. However, over time, these springs may wear out or become damaged, necessitating a replacement. In this blog post, we will discuss the factors to consider when selecting the right air spring replacement for your truck.

Listed below are some key points to keep in mind:

1. Compatibility: The first and foremost factor to consider is the compatibility of the air spring replacement with your truck’s make and model. Each manufacturer produces air springs specifically designed for particular truck brands, so it is crucial to choose a replacement that is a perfect fit for your vehicle.

2. Load Capacity: Another important consideration is the load capacity of the air spring replacement. The load capacity determines the maximum weight that the air spring can support. It is essential to choose a replacement that matches the load requirements of your truck to ensure optimal performance.

3. Durability and Quality: The durability and quality of the air spring replacement are crucial factors that directly impact its lifespan and performance. Inferior quality replacements may wear out quickly or fail to withstand heavy loads, leading to frequent replacements and potentially compromising the safety and stability of your truck. Therefore, opt for reputable brands known for their high-quality air springs.

| Factors to Consider: | Points to Remember: |

|---|---|

| Compatibility | Choose a replacement that is compatible with your truck’s make and model. |

| Load Capacity | Select a replacement that matches the load requirements of your truck. |

| Durability and Quality | Opt for reputable brands known for their high-quality air springs. |

By considering these factors and conducting thorough research, you can make an informed decision when choosing the right air spring replacement for your truck. It is advisable to consult with a professional or seek guidance from experienced technicians to ensure you select the most suitable replacement that meets the specific needs of your truck and provides optimal performance and durability.

The Role of Proper Inflation in Air Spring Performance

In the world of trucks and heavy-duty vehicles, air springs play a crucial role in providing comfort, stability, and control. These pneumatic devices, also known as airbags, are responsible for supporting the weight of the vehicle, absorbing shocks from uneven road surfaces, and maintaining proper ride height.

Proper inflation is a vital factor that directly affects the performance and longevity of air springs. When it comes to airbags, keeping them inflated to the correct pressure is essential for optimal functionality. Let’s explore the role of proper inflation in air spring performance and why it is crucial for truck owners and operators.

1. Enhanced Performance: When air springs are inflated to the manufacturer-recommended pressure, they operate at their highest level of efficiency. Proper inflation helps distribute the weight evenly across all springs, ensuring that each airbag carries its fair share of the load. This leads to improved stability, control, and overall performance of the vehicle, especially when navigating rough terrains or carrying heavy payloads.

2. Increased Lifespan: Just like any other automotive component, air springs also have a limited lifespan. However, by maintaining proper inflation, you can significantly extend their longevity. Under-inflated or over-inflated airbags experience excessive strain and wear, which can lead to premature failure. On the other hand, well-inflated air springs experience less stress, reducing the chances of damage and increasing their lifespan.

3. Fuel Efficiency: Properly inflated air springs contribute to better fuel economy. When the airbags are correctly inflated, the truck’s suspension system operates optimally, resulting in improved aerodynamics and reduced drag. This, in turn, requires less power to overcome resistance, leading to fuel savings over the long run.

Proper inflation of air springs is not a one-time task; it requires regular attention and maintenance. Truck owners and operators should follow these tips to ensure the correct inflation of their airbags:

| Tips for Proper Inflation: |

|---|

| 1. Refer to the vehicle’s manual or consult with an expert to determine the recommended pressure for the air springs. |

| 2. Use a reliable pressure gauge to check the current pressure of the airbags regularly. |

| 3. Adjust the inflation level if necessary, keeping it within the recommended range. |

| 4. Inspect the air springs for signs of wear, leaks, or damage during routine maintenance checks. |

| 5. If unsure, seek professional assistance to ensure accurate inflation and overall air spring health. |

In conclusion, proper inflation plays a crucial role in the performance and lifespan of air springs in trucks. By maintaining the correct pressure, truck owners can enhance the overall performance, increase the longevity of the airbags, and even improve fuel efficiency. Regular inspections and adhering to manufacturer guidelines are vital to ensure the optimal functioning of air springs. Don’t overlook the importance of proper inflation, as it can greatly impact the comfort, stability, and control of your heavy-duty vehicle.

Tips for Extending the Lifespan of Air Springs

Air springs play a crucial role in the suspension system of trucks, providing support and cushioning to the vehicle. As a truck owner or operator, it is important to understand the significance of extending the lifespan of air springs. By taking proper care and following a few key tips, you can ensure that your air springs last longer, saving you time and money.

Regular inspection and maintenance: One of the most important tips for extending the lifespan of air springs is to perform regular inspections and maintenance. Check for any signs of wear, tear, or damage on a routine basis. Look out for cracks, leaks, or uneven wear. By catching any issues early on, you can prevent further damage and extend the life of your air springs.

Proper inflation: Maintaining the proper inflation levels is essential for optimal air spring performance and longevity. Underinflated air springs can lead to excessive strain on other suspension components, while overinflation can cause early wear and tear. Always refer to the manufacturer’s guidelines and use a reliable pressure gauge to ensure the air springs are inflated to the recommended pressure.

Avoid overloading: Overloading your truck can put excessive stress on the air springs and other suspension components. Ensure that you adhere to the weight limits specified by the manufacturer and avoid exceeding the recommended load capacity. Overloading can cause premature wear and reduce the lifespan of your air springs.

Protect from contaminants: Air springs are susceptible to damage from debris, chemicals, and other contaminants. Avoid driving on rough terrain or through areas with sharp and abrasive materials. If you operate in dusty or corrosive environments, consider installing protective covers or shields to shield the air springs from potential damage. Regularly clean the air springs and surrounding areas to remove any dirt or debris that may have accumulated.

| Signs of Wear and Tear | Possible Causes |

|---|---|

| Cracks or tears on the air spring surface | Age, excessive stress, or inadequate maintenance |

| Leaking air or loss of pressure | Damage to the air spring or valves |

| Uneven wear on the air spring | Improper alignment, overloading, or lack of maintenance |

Seek professional maintenance: While regular inspections and maintenance can go a long way, it is also recommended to seek professional air spring maintenance services. Qualified technicians have the expertise and specialized tools to thoroughly inspect, diagnose, and repair any issues with your air springs. They can also provide guidance on proper maintenance practices, ensuring the longevity of your air springs.

Conclusion: Taking proactive measures to extend the lifespan of air springs in trucks is essential for optimal performance and cost-effectiveness. By implementing the tips mentioned above – regular inspection and maintenance, proper inflation, avoiding overloading, protecting from contaminants, and seeking professional maintenance when necessary – you can significantly increase the lifespan of your air springs. Remember, prioritizing the care and longevity of your air springs not only improves the overall performance of your truck but also contributes to a safer and smoother ride.

Professional Air Spring Maintenance Services

When it comes to maintaining the performance and functionality of your truck’s air springs, it is essential to seek professional air spring maintenance services. These services are specifically designed to ensure that your air springs are in optimal condition, providing you with a safe and smooth ride. By entrusting the maintenance of your air springs to skilled professionals, you can avoid potential issues and enjoy the full benefits of this crucial component of your truck’s suspension system.

One of the key advantages of opting for professional air spring maintenance services is the expertise and experience that technicians bring to the table. With their in-depth knowledge of air spring systems, they can detect potential problems and perform necessary repairs or replacements before major issues arise. By conducting regular inspections, these professionals can identify any signs of wear and tear, as well as address any underlying problems affecting the performance of your air springs.

Furthermore, professional maintenance services often utilize content-rich practices to ensure thorough and comprehensive servicing. This may include the use of checklists or guidelines that cover key areas such as inspection, cleaning, lubrication, and adjustment. By adhering to these practices, technicians can ensure that all aspects of your air spring system are thoroughly examined and serviced, leaving no room for potential issues to go unnoticed.

- Regular inspections: During a professional air spring maintenance service, technicians will inspect the overall condition of your air springs. This includes checking for any signs of damage, leaks, or abnormalities in the air spring system.

- Cleaning and lubrication: Proper cleaning and lubrication of air springs are crucial for their optimal performance. Professional services ensure that all components are cleaned and lubricated appropriately, improving the overall lifespan of the air springs.

- Adjustment and alignment: Technicians will also check the alignment and adjustment of your air springs. This step is crucial to maintain the balance and stability of your vehicle’s suspension system.

| Benefits of Professional Air Spring Maintenance Services |

|---|

| 1. Enhanced Safety: Professionals can identify potential issues and address them promptly, ensuring that your air springs function properly and provide a safe driving experience. |

| 2. Improved Performance: Regular maintenance services can optimize the performance of your air springs, enhancing the overall comfort and stability of your truck. |

| 3. Longevity of Air Springs: By addressing minor problems and conducting necessary repairs, professionals can extend the lifespan of your air springs, saving you from costly replacements. |

| 4. Cost Savings: Investing in professional maintenance services can help you avoid major repairs or replacements in the long run, reducing overall expenses. |

By opting for professional air spring maintenance services, you can ensure that this vital component of your truck’s suspension system remains in top-notch condition. From regular inspections to meticulous cleaning and necessary adjustments, professionals have the expertise and resources to keep your air springs performing at their best. With enhanced safety, improved performance, and a longer lifespan for your air springs, investing in professional maintenance services is a prudent choice for any truck owner.

Troubleshooting Air Spring Problems

When it comes to the performance and functionality of trucks, air springs play a crucial role. These mechanical components are responsible for maintaining a smooth and comfortable ride, as well as supporting heavy loads. However, like any other vehicle part, air springs can encounter problems and malfunctions over time. In this blog post, we will discuss common air spring problems that truck owners may face and provide some troubleshooting tips to help resolve these issues.

1. Air Leaks: One of the most common problems with air springs is air leaks. This occurs when there is a rupture or puncture in the air spring, causing it to lose air pressure. An easy way to identify an air leak is to listen for a hissing sound near the air spring. To fix this issue, you can start by inspecting the air lines and connections for any signs of damage. If a leak is detected, it is advisable to replace the damaged part as soon as possible to prevent further damage.

2. Uneven Ride Height: Another issue that truck owners may encounter with air springs is an uneven ride height. This can occur when one side of the vehicle sits higher or lower than the other. To troubleshoot this problem, you can check the air pressure in each air spring using a pressure gauge. If there is a significant difference in air pressure between the springs, you may need to adjust or replace the faulty spring to ensure an even ride height.

3. Suspension Failure: Air springs are an integral part of the vehicle’s suspension system. If you notice a sudden decrease in the overall suspension performance, it could be a sign of air spring failure. This can lead to a bumpy ride and decreased stability. To troubleshoot this problem, inspect the air springs for any signs of physical damage or wear and tear. If the springs appear to be worn out or damaged, it is recommended to replace them with new ones to ensure optimal suspension performance.

In conclusion, troubleshooting air spring problems in trucks is essential to maintain their overall performance and safety. By being aware of common issues such as air leaks, uneven ride height, and suspension failure, truck owners can take appropriate measures to resolve these problems. Regular inspections and maintenance of air springs are key to detecting and addressing any issues before they escalate. Remember, when it comes to air spring problems, it is always recommended to consult with a professional technician or seek professional air spring maintenance services for proper diagnosis and repairs.