Are you tired of the rough ride that comes with traditional truck suspensions? If so, it may be time to consider upgrading to an air ride truck suspension. In this blog post, we will explore what air ride truck suspension is, the advantages it offers, the components involved, and how it works. We will also provide tips on choosing the right system, the installation process, and maintenance tips. Additionally, we will discuss common problems with air ride truck suspension and how upgrading your suspension can enhance your truck’s performance. So, let’s dive in and discover the wonders of air ride truck suspension!

What is air ride truck suspension?

Air ride truck suspension is a type of suspension system used in trucks that utilizes air springs instead of traditional coil springs or leaf springs. It is designed to provide a smoother, more comfortable ride by adjusting the air pressure in the springs to match the weight of the load being carried by the truck.

One of the main advantages of air ride truck suspension is its ability to improve the overall ride quality. The system can be adjusted to provide a softer or firmer ride, depending on the preferences of the driver. This can be particularly beneficial for long-haul truckers who spend extended periods of time on the road.

The components of an air ride truck suspension system typically include air springs, air compressors, air tanks, height control valves, and electronic controls. The air springs, also known as air bags, are the primary components responsible for supporting the weight of the truck and providing the desired level of ride comfort.

- Advantages of air ride truck suspension:

- Improved ride quality

- Adjustable to different load weights

- Reduced wear and tear on the truck

- Enhanced stability and control

- Reduced driver fatigue

| Component | Description |

|---|---|

| Air Springs | Hollow rubber or synthetic bags filled with compressed air, responsible for supporting the weight of the truck. |

| Air Compressors | Devices that compress and store air in the air tanks to maintain the desired air pressure in the air springs. |

| Air Tanks | Reservoirs that store compressed air for immediate use by the air suspension system. |

| Height Control Valves | Valves that monitor and adjust the ride height of the truck by controlling the air pressure in the air springs. |

| Electronic Controls | Systems that provide advanced control and monitoring of the air ride truck suspension, allowing for automatic adjustments and personalized settings. |

Advantages of air ride truck suspension

When it comes to truck suspension systems, air ride suspension has gained popularity in recent years. This innovative technology offers several advantages over traditional suspension systems, making it a preferred choice for many truck owners. In this blog post, we will explore the various benefits of air ride truck suspension.

1. Improved ride comfort: One of the biggest advantages of air ride suspension is the enhanced ride comfort it provides. With air springs instead of conventional steel springs, the suspension system can absorb shocks and vibrations more effectively. This results in a smoother and more comfortable ride, even on uneven or bumpy roads.

2. Better load handling: Air ride suspension systems are designed to adjust the height and stiffness of the suspension based on the load being carried by the truck. This feature enables the suspension to adapt to different load conditions, ensuring optimal performance and handling. Whether the truck is fully loaded or empty, air ride suspension provides a stable and balanced ride.

3. Reduced maintenance: Another advantage of air ride truck suspension is the reduced need for maintenance. Unlike traditional suspension systems that require frequent checks and replacement of worn-out parts, air ride suspension is generally more durable and requires less maintenance. This not only saves time but also reduces costs in the long run.

In conclusion, air ride truck suspension offers several advantages that make it a favorable choice for truck owners. By providing improved ride comfort, better load handling, and reduced maintenance requirements, it enhances overall driving experience and ensures the longevity of the suspension system. If you are considering upgrading your truck’s suspension, air ride suspension can be an excellent option to explore.

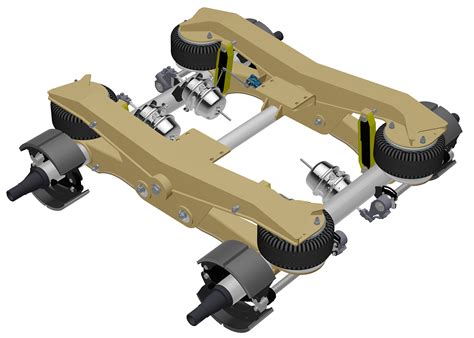

Components of air ride truck suspension

The components of an air ride truck suspension system are essential to its overall performance and functionality. The system consists of several key parts that work together to provide a smooth and comfortable ride for both the driver and passengers.

One of the main components of an air ride truck suspension system is the air springs. These springs are responsible for supporting the weight of the vehicle and absorbing road shocks and vibrations. They are typically made from flexible rubber and are inflated with air to provide the desired level of support and cushioning. Air springs can be adjusted to different pressures to accommodate varying loads and road conditions.

Another important component of an air ride truck suspension system is the air compressor. This device is responsible for inflating the air springs to the desired pressure. The compressor draws in air from the atmosphere and compresses it before delivering it to the springs. The compressor is usually powered by the vehicle’s engine or an electric motor, and it is equipped with a pressure switch that ensures the springs are always maintained at the correct pressure.

The control system is another crucial component of an air ride truck suspension. This system is responsible for regulating the air pressure in the springs and maintaining the desired ride height. The control system typically consists of air valves, sensors, and an electronic control module. The sensors monitor the height and load of the vehicle and send signals to the control module, which adjusts the air pressure accordingly. This ensures that the vehicle remains level and stable, even when carrying heavy loads or driving on uneven terrain.

Other components of an air ride truck suspension system include air lines, fittings, and an air tank. The air lines and fittings transport the compressed air from the compressor to the springs, while the air tank stores the compressed air and helps regulate the system’s pressure. These components are essential for the proper functioning of the system and should be regularly inspected and maintained to prevent any leaks or failures.

In conclusion, the components of an air ride truck suspension system work together to provide a comfortable and controlled ride. The air springs, air compressor, control system, air lines, fittings, and air tank all play a vital role in ensuring that the suspension system operates efficiently and effectively. Regular maintenance and inspection of these components are essential to prolong the lifespan of the system and prevent any potential issues or failures.

How does air ride truck suspension work?

Air ride truck suspension is a type of suspension system that uses air springs or air bags to control the height and stiffness of the suspension. It is commonly found on trucks, trailers, and buses, and is designed to provide a smooth and comfortable ride, especially when carrying heavy loads or towing. The air springs or bags are filled with compressed air, which can be adjusted to increase or decrease the amount of support and cushioning provided by the suspension.

One of the key advantages of air ride truck suspension is its ability to adjust the ride height. By increasing or decreasing the air pressure in the air springs, the suspension can be raised or lowered to accommodate different road conditions or loading requirements. This allows the driver to maintain optimal ride height and stability, reducing the risk of bottoming out or swaying.

In addition to height adjustment, air ride truck suspension also offers adjustable stiffness or damping. By adjusting the air pressure in the air bags, the stiffness of the suspension can be increased or decreased. This allows the driver to fine-tune the suspension to balance comfort and handling, providing a smooth ride on rough roads or a more responsive and sporty feel on smooth highways.

The components of an air ride truck suspension system include air springs, air valves, air compressors, and control modules. The air springs are responsible for supporting the weight of the vehicle and providing the desired ride height and stiffness. The air valves control the flow of air in and out of the air springs, allowing for adjustment of the suspension. The air compressors are used to fill the air springs with compressed air, while the control modules monitor and regulate the suspension system.

In terms of how air ride truck suspension works, when the vehicle encounters a bump or uneven surface, the air springs compress or expand to absorb the impact and cushion the ride. The air valves control the flow of air in and out of the air springs, allowing the suspension to adjust its height and stiffness to maintain stability and comfort. The control modules regulate the air pressure in the air springs based on the driver’s settings or the vehicle’s load, ensuring optimal performance.

To summarize, air ride truck suspension works by utilizing air springs or air bags to control the height and stiffness of the suspension. The adjustable ride height and damping provide a smooth and comfortable ride, while the components such as air valves, compressors, and control modules ensure optimal performance. Whether you’re driving a truck, trailer, or bus, air ride truck suspension offers a versatile and customizable suspension system that enhances both comfort and handling.

Choosing the right air ride suspension system

When it comes to choosing the right air ride suspension system for your truck, there are several factors to consider. Choosing the right system is crucial as it can greatly impact the performance and comfort of your vehicle. Here are some key points to keep in mind:

1. Weight Capacity: One of the most important factors to consider is the weight capacity of the suspension system. Different systems have different weight limits, so it’s important to choose one that can adequately support the weight of your truck and any additional load you may be carrying.

2. Adjustability: Another important factor is the adjustability of the suspension system. Some systems allow you to easily adjust the ride height and stiffness, which can be beneficial if you frequently carry heavy loads or want to customize the ride quality to your preferences.

3. Durability: It’s important to choose a suspension system that is durable and built to last. Look for systems that are made from high-quality materials and have a reputation for withstanding tough conditions. This will ensure that your suspension system can handle the rigors of off-roading or heavy-duty use.

4. Compatibility: Before purchasing a suspension system, make sure it is compatible with your specific make and model of truck. It’s also important to consider any modifications or additional components that may be required for installation.

5. Budget: Last but not least, consider your budget. Air ride suspension systems can vary greatly in price, so it’s important to determine how much you are willing to invest. Remember, while it may be tempting to opt for a cheaper system, investing in a higher-quality system can provide better performance and longevity in the long run.

In conclusion, choosing the right air ride suspension system for your truck requires careful consideration of factors such as weight capacity, adjustability, durability, compatibility, and budget. By taking the time to assess your needs and research different options, you can make an informed decision that will enhance the performance and comfort of your vehicle.

Installation process of air ride truck suspension

Installation Process of Air Ride Truck Suspension

Installing air ride truck suspension can greatly enhance the performance and comfort of your vehicle. In this blog post, we will guide you through the step-by-step installation process of air ride truck suspension. From preparing the tools and equipment to the final adjustments, we will cover all the essential aspects to help you successfully install your air ride truck suspension system.

| Tools | Equipment |

|---|---|

| Sockets and wrenches | Air compressor |

| Jack and jack stands | Air suspension kit |

| Torque wrench | Air tubing and fittings |

| Air impact gun | Wiring harness |

| Wire strippers | Control module |

Before starting the installation process, make sure to gather all the necessary tools and equipment. This will ensure a smooth and efficient installation. The key tools you will need include sockets and wrenches, a jack and jack stands, a torque wrench, an air impact gun, and wire strippers. Additionally, you will require an air compressor, an air suspension kit, air tubing and fittings, a wiring harness, and a control module.

Once you have everything ready, begin by lifting your truck with the jack and securing it with the jack stands. This will provide a stable platform for the installation process. Next, remove the existing suspension components, such as the shocks and leaf springs, if necessary. Follow the manufacturer’s instructions to properly disconnect and remove the old components.

After removing the old suspension components, it’s time to install the air ride suspension system. Start by mounting the airbags or air springs in their designated locations under the truck. Ensure that all connections are secure and tighten them using the appropriate tools. Then, install the air tubing and fittings, connecting them to the airbags and the air compressor. Use zip ties or brackets to secure the tubing along the frame of the truck.

Once the airbags and tubing are securely in place, proceed to install the wiring harness and control module. The wiring harness is responsible for connecting the control module to the truck’s battery and other electrical components. Follow the provided instructions to properly route and connect the wiring harness, ensuring that all connections are secure and insulated.

Finally, double-check all the connections and make any necessary adjustments. Lower the truck from the jack stands and test the functionality of the air ride suspension system. Gradually inflate the airbags and check for any leaks or abnormal sounds. Adjust the air pressure according to your desired ride height and comfort.

By following this step-by-step installation process, you can successfully install air ride truck suspension system in your vehicle. Always refer to the manufacturer’s instructions and seek professional assistance if needed. With a properly installed air ride suspension system, you can enjoy a smoother ride and improved handling on various terrains.

Maintenance tips for air ride truck suspension

Maintenance Tips for Air Ride Truck Suspension

When it comes to maintaining your air ride truck suspension, regular care and attention are key. By keeping up with proper maintenance, you can ensure that your suspension system continues to function optimally, providing you with a smooth and comfortable ride. In this blog post, we will discuss some essential maintenance tips for air ride truck suspension systems.

1. Regularly Inspect Components

One of the most important maintenance tasks for air ride truck suspension is to regularly inspect all the components. This includes checking the air bags, shocks, valves, and air lines for any signs of wear or damage. Look for leaks, cracks, or loose fittings and replace or repair any faulty parts immediately. Regular inspections will help prevent any potential issues from escalating and ensure the longevity of your suspension system.

2. Keep Air Bags Clean

The air bags are a crucial part of the air ride truck suspension system, as they provide the necessary support and cushioning. It is essential to keep them clean and free from debris, as dirt and grime can cause damage over time. Regularly clean the air bags with mild soap and water, and avoid using harsh chemicals or abrasive materials that could potentially harm the bags.

3. Maintain Proper Air Pressure

Proper air pressure is vital for the optimal functioning of air ride truck suspension. It is recommended to check the air pressure in the system regularly, using a reliable gauge. Ensure that the air pressure is at the manufacturer’s recommended level. Low air pressure can result in a rough ride and diminished performance, while overinflating can cause damage to the system components. Maintain the appropriate air pressure to ensure a smooth and safe ride.

4. Follow Manufacturer’s Guidelines

Each air ride truck suspension system may have specific maintenance requirements outlined by the manufacturer. It is essential to familiarize yourself with these guidelines and follow them diligently. These guidelines may include information on recommended maintenance intervals, lubrication points, and specific checks to be performed. Adhering to the manufacturer’s instructions will help prolong the life of your suspension system and prevent unnecessary issues.

5. Seek Professional Assistance

If you are unsure about any aspect of maintaining your air ride truck suspension or notice any significant issues, it is advisable to seek professional assistance. Qualified technicians or suspension specialists will have the expertise and knowledge to diagnose any problems accurately and provide the necessary repairs or replacements. Ignoring or attempting to fix complex issues without professional assistance can lead to further damage or safety hazards.

By implementing these maintenance tips for your air ride truck suspension system, you can ensure its longevity and enhance your overall driving experience. Regular inspections, proper cleaning, maintaining air pressure, following manufacturer’s guidelines, and seeking professional help when needed will help keep your suspension system in excellent condition for years to come.

Common problems with air ride truck suspension

When it comes to air ride truck suspension systems, there can be a variety of common problems that truck owners may encounter. It is important to be aware of these issues in order to properly maintain and troubleshoot your suspension system. In this blog post, we will explore some of the most frequently reported problems with air ride truck suspension and provide tips on how to address them.

1. Leaks: One of the most common issues with air ride truck suspension systems is air leaks. These leaks can be caused by a variety of factors, such as worn-out seals, damaged air lines, or faulty air bags. If you notice a decrease in the overall performance of your suspension or hear a hissing sound when the system is engaged, it may indicate a leak. To address this problem, it is recommended to thoroughly inspect the suspension components and repair or replace any damaged parts.

2. Uneven Ride Height: Another problem that truck owners may face is an uneven ride height. This means that one side of the truck is higher or lower than the other, resulting in an imbalanced ride. Uneven ride height can be caused by a variety of factors, such as air leaks, worn-out components, or improper weight distribution. To address this issue, it is important to check for any air leaks and ensure that all suspension components are in good condition. Additionally, make sure that the truck is loaded and balanced properly to prevent uneven ride height.

3. Poor Performance: Poor performance is another common problem with air ride truck suspension systems. This can manifest as a rough or bumpy ride, excessive bouncing, or an overall decrease in the suspension’s ability to absorb shocks and vibrations. Poor performance can be caused by worn-out air bags, damaged valves, or insufficient air pressure. To address this problem, it is recommended to regularly inspect and maintain the suspension system, including checking the air pressure, replacing worn-out components, and ensuring proper alignment and balance.

| Common Problems | Possible Causes | Solutions |

|---|---|---|

| Leaks | Worn-out seals, damaged air lines, faulty air bags | Thoroughly inspect and repair or replace damaged parts |

| Uneven Ride Height | Air leaks, worn-out components, improper weight distribution | Check for air leaks, ensure good condition of components, and properly balance the truck |

| Poor Performance | Worn-out air bags, damaged valves, insufficient air pressure | Regularly inspect and maintain the suspension system, including proper air pressure, component replacement, and alignment |

In conclusion, common problems with air ride truck suspension systems include leaks, uneven ride height, and poor performance. It is crucial to promptly address these issues in order to maintain the functionality and safety of your suspension system. Regular inspection, proper maintenance, and timely repair or replacement of damaged components are key to ensuring a smooth and reliable ride for your truck.

Upgrading your truck suspension for better performance

When it comes to upgrading your truck suspension for better performance, there are several factors to consider. A well-performing suspension system can greatly improve the overall driving experience and handling of your truck. Whether you use your truck for daily commuting or off-road adventures, upgrading your suspension can provide a smoother ride, increased stability, and enhanced control. In this blog post, we will explore the various aspects of upgrading your truck suspension and the benefits it can bring.

One of the key advantages of upgrading your truck suspension is the ability to customize it according to your specific needs. There are different types of suspension systems available, such as coilover, air ride, and leaf spring, each with their own set of advantages and disadvantages. By carefully selecting the right suspension system for your truck, you can tailor it to meet your desired performance and comfort levels. This level of customization is especially beneficial for truck owners who engage in heavy-duty towing, off-roading, or have specific load-carrying requirements.

Upgrading your truck suspension can also significantly improve the handling and stability of your vehicle. A well-designed suspension system helps keep your truck balanced, reducing body roll and preventing excessive weight transfer during cornering or sudden maneuvers. This enhanced stability not only makes driving safer, but also improves overall control, especially in challenging road conditions or off-road terrains. Upgraded suspension components, such as high-performance shock absorbers and sway bars, can further enhance these benefits by improving damping characteristics and reducing body movement.

When upgrading your truck suspension, it is important to consider the quality and durability of the components you choose. Investing in high-quality suspension parts ensures longevity and reliability, preventing premature wear and failure. Additionally, a properly upgraded suspension system can also increase the lifespan of other truck components, such as tires and brakes, by reducing excessive stress and wear. Regular maintenance and inspections are also crucial to ensure optimal performance and to address any issues before they become major problems.

- Increased customizability

- Enhanced handling and stability

- Improved control in challenging conditions

- Extended lifespan of truck components

- Better performance and driving experience

| Component | Description |

|---|---|

| Coilovers | Combines a shock absorber and coil spring in a single unit, providing adjustable ride height and damping settings. |

| Air ride | Utilizes air springs to provide a cushioned and adjustable ride, offering improved comfort and load-carrying capacity. |

| Leaf springs | Consist of multiple layers of metal strips that support the weight of the truck, commonly used in heavy-duty applications. |

| Shock absorbers | Dampen the vibrations and oscillations produced by irregularities in the road surface, enhancing comfort and control. |

| Sway bars | Connect the suspension components on either side of the vehicle, reducing body roll during cornering for improved stability. |

Overall, upgrading your truck suspension can significantly enhance the performance, handling, and comfort of your vehicle. The ability to customize your suspension system, combined with the improved stability and control, makes it a worthwhile investment for truck owners. By selecting high-quality components and providing regular maintenance, you can ensure optimal performance and prolong the lifespan of your truck. So, don’t hesitate to explore the various options available and upgrade your truck suspension to enjoy a better driving experience like never before.